CLAREX® DR-IIICX Light Diffusion Filter

Light diffusion filter for color or monochrome LCD display

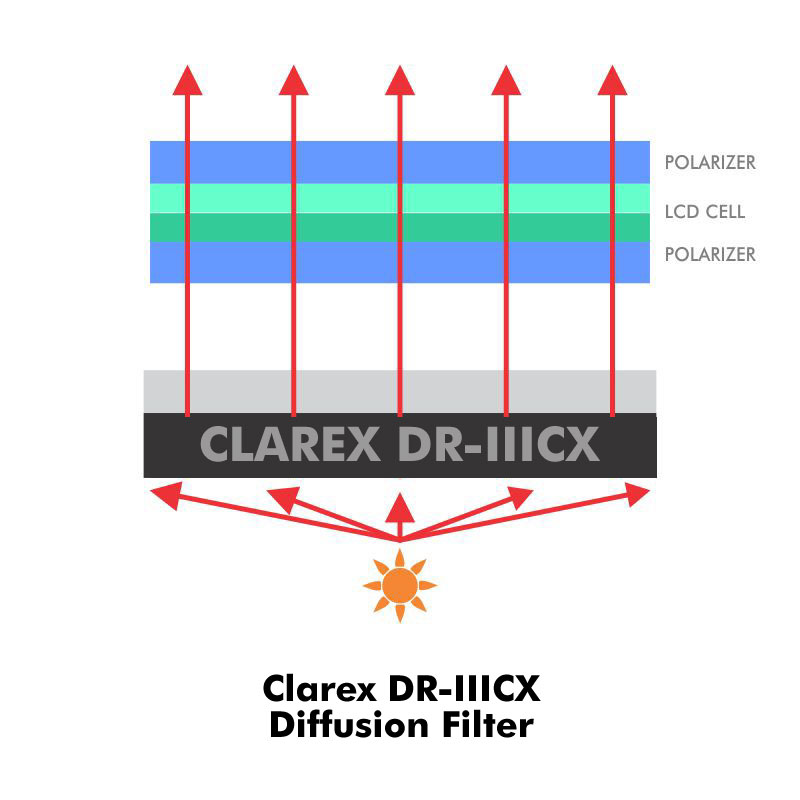

CLAREX® DR-IIICX LIGHT DIFFUSION FILTER - is an optical light diffusion filter combining light transmission with uniformly controlled diffusion. DR-IIICX light diffusing filters are available with light transmissions from 45% - 93%. They are adaptable to any backlit display. These filters can be color matched and produced to custom light transmission per the customer's requirement. (Subject to minimum quantity requirements).

- Light transmissions from 45% - 93%

- UV-blocking (Available as UV-Pass upon request)

- No Newton's Ring!

- Weather resistant

- Has a color temperature of 6750K

APPLICATIONS - Light diffusion filter for color or monochrome LCD display.

THICKNESS - 0.2mm and 2.0mm

SIZE - 400mm x 550mm standard. Custom sizes available upon request.

MACHINING / PRINTING - available to customer specification.

COLORS - White is standard – other colors available upon request.

DOWNLOADS - Astra Products Brochure

| LIGHT TRANSMISSION - THICKNESS | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PROD NO | LIGHT TRANS | THICKNESS | ||||||||

| DR-45CX | 45% | 2.0mm | ||||||||

| DR-50CX | 50% | 2.0mm | 1.5mm | |||||||

| DR-55CX | 55% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | |||||

| DR-60CX | 60% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | 0.6mm | ||||

| DR-65CX | 65% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | 0.6mm | 0.5mm | |||

| DR-70CX | 70% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | 0.6mm | 0.5mm | 0.4mm | ||

| DR-75CX | 75% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | 0.6mm | 0.5mm | 0.4mm | ||

| DR-80CX | 80% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | 0.6mm | 0.5mm | 0.4mm | 0.3mm | |

| DR-85CX | 85% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | 0.6mm | 0.5mm | 0.4mm | 0.3mm | |

| DR-90CX | 90% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | 0.6mm | 0.5mm | 0.4mm | 0.3mm | 0.2mm |

| DR-93CX | 93% | 2.0mm | 1.5mm | 1.0mm | 0.8mm | 0.6mm | 0.5mm | 0.4mm | 0.3mm | 0.2mm |

| OPTICAL PROPERTIES | |||||

|---|---|---|---|---|---|

| Grade No. | Color Temperature | Total Light Transmission | Diffuse Light Transmission | Parallel Light Transmission | Haze |

| DR-45CX | 6750K | 45% | 43% | 2% | 96% |

| DR-50CX | 6750K | 50% | 48% | 2% | 96% |

| DR-55CX | 6750K | 55% | 53% | 2% | 96% |

| DR-60CX | 6750K | 60% | 58% | 2% | 96% |

| DR-65CX | 6750K | 65% | 62% | 3% | 96% |

| DR-70CX | 6750K | 70% | 67% | 3% | 96% |

| DR-75CX | 6750K | 75% | 72% | 3% | 96% |

| DR-80CX | 6750K | 80% | 77% | 3% | 96% |

| DR-85CX | 6750K | 85% | 81% | 4% | 96% |

| PHYSICAL PROPERTIES | |||

|---|---|---|---|

| PROPERTY | METHOD | UNIT | VALUE |

| Reflective Index | ASTM D-542 | 1.49 | |

| Heat Distortion Temperature | ASTM D-648 | °C | 110 |

| Maximum Recommended Continuous Temperature | °C | 80 | |

| Available with higher temperature ratings on request, 90-95ºC | |||

| Coefficient of Thermal Expansion | ASTM D-696 | cm/cm/°C | 7 x 10-5 |

| Pencil Hardness | 2H | ||

| Heat Resistance | 80°C x 100hr | No Change | |

| Cold Resistance | -40°C x 100hr | No Change | |

| Humidity Resistance | 60°C x 90% x 100hr | No Change | |

| Thermal Cycle | -40°C<->80°C (10 cycles) |

No Change | |

| CHEMICAL PROPERTIES | |

|---|---|

| REAGENT | CHANGE OF APPEARANCE |

| Ethyl Alcohol (50%) | No Change |

| Isopropyl Alcohol | No Change |

| Soap Aqua Solution | No Change |

| Benzene | Swollen |

Related Products