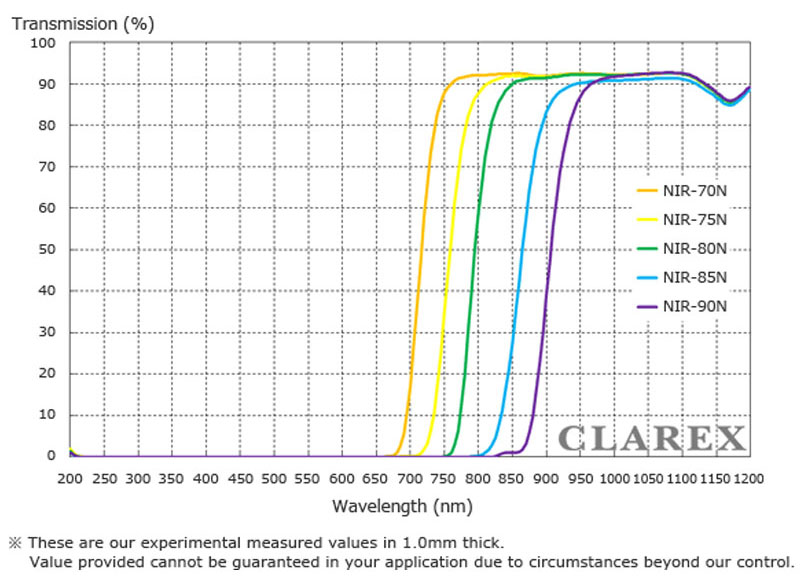

CLAREX® Near-Infrared (NIR) Filters

Optical Grade Longpass NIR Filters available in a variety of configurations to meet your needs

Download: Clarex® NIR Filter Information Sheet

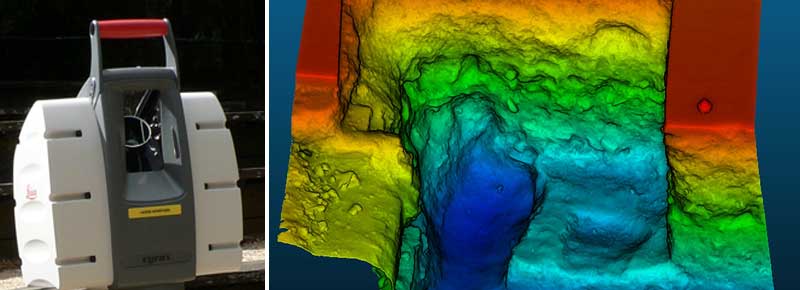

Typical uses include LiDAR instrumentation, Time of Flight sensors

CLAREX® NIR FILTERS - transmit Near Infrared (IRT) light and absorbs visible light. There are 6 types of Near Infrared filters which transmit through the ranges of 670nm to 910nm.

- Transmit Near Infrared light and absorbs visible

- Excellent optical characteristics

- No double refraction

- Available smooth surface or anti-glare surface

- Available scratch-resistant

- Available with custom-tuned antireflection coating

APPLICATIONS - Instrumentation, Sensors, Communications and Optical Devices, LIDAR filters, Machine-Vision, Time of Flight Sensors, Covert Imaging & Illumination

THICKNESS - 0.5, 0.6, 0.7, 0.8, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0mm

SIZE - 400mm x 550mm standard. Custom sizes available upon request.

MACHINING / PRINTING - Available to customer specification. See more about our fabrication capabilities.

Need a higher cut-in?

Click the image to see the transmission curve for our new addition: NIR-911N at 910nm.

Need a higher cut-in?

Click the image to see the transmission curve for our new addition: NIR-911N at 910nm.

| Type No. | Color Tone | Near Infrared transmission |

|---|---|---|

| NIR-70N | Black | Transmit from 670nm |

| NIR-75N | Black | Transmit from 730nm |

| NIR-80N | Black | Transmit from 760nm |

| NIR-85N | Black | Transmit from 810nm |

| NIR-90N | Black | Transmit from 860nm |

|

NIR-911N |

Black | Transmit from 910nm |

Physical & Chemical Properties of CLAREX® Near-Infrared (NIR) Filters

| PHYSICAL PROPERTIES | ||||

|---|---|---|---|---|

| PROPERTY | METHOD | UNIT | Normal Grade | Hard Coat Grade |

| SPECIFIC GRAVITY | ASTM D-792 | 1.19 | 1.19 | |

| OPTICAL | ||||

| Refractive Index | ASTM D-542 | 1.49 | 1.49 (1.54) | |

| MECHANICAL | ||||

| Elongation | ASTM D-638 | % | 5 | 5 |

| Tensile Rupture Strength | ASTM D-638 | kg/cm2 | 750 | 650 |

| Flexural Rupture Strength | ASTM D-790 | kg/cm2 | 1200 | 800 |

| THERMAL | ||||

| Heat Distortion Temperature | ASTM D-648 | ºC | 110 | 110 |

| Maximum recommended continuous temperature | ºC | 80 | 80 | |

| Available with higher temperature ratings on request, 90-95ºC | ||||

| Coefficient of Thermal Expansion | ASTM D-696 | cm/cm/ºC | 7 x 10-5 | 7 x 10-5 |

| Specific Heat | ASTM D-638 | cal/grºC | 0.3535 | 0.35 |

| DURABILITY | ||||

| Heat Resistance | 80ºC x 100hr | No Change | No Change | |

| Cold Resistance | -40ºC x 100hr | No Change | No Change | |

| Humidity Resistance | 60ºC x 90% x 100hr | No Change | No Change | |

| Thermal Cycle | -40ºC <> 80ºC (10 cycles) | No Change | No Change | |

| ELECTRICAL | ||||

| Surface Resistivity | W | >1016 | >1016 | |

| CHEMICAL | ||||

| Methyl Alcohol (50%) | No Change | No Change | ||

| Ethyl Alcohol (50%) | No Change | No Change | ||

| Soap Aqua Solution | No Change | No Change | ||

| Toluene | Dissolved | No Change | ||

| Acetone | Dissolved | No Change | ||

| Benzene | Swollen | No Change | ||

| Ethylene Dichloride | Dissolved | No Change | ||

| + | ||||

| PENCIL HARDNESS | 2H | 6~8H | ||

| ADHESION | K-5400 | 100/100 | ||

| FLAMMABILITY | ||||

| UL standard | >=0.8mm Thickness |

94HB | 94HB | |