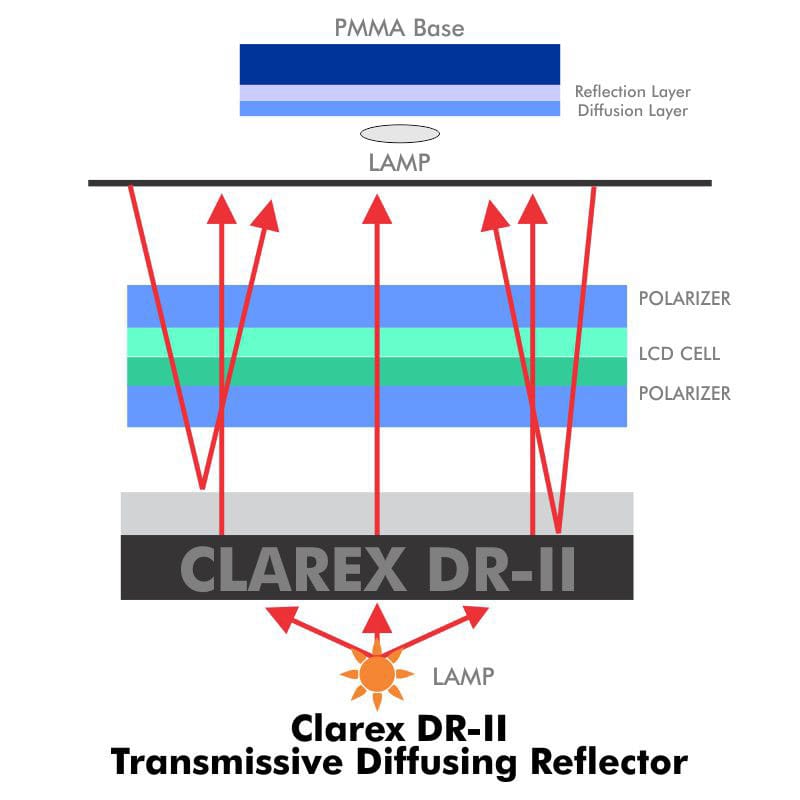

CLAREX Diffusion Transflectors (DR-II)

One material offering both diffused reflection as well as diffused transmission.

CLAREX DR-II Transflectors will diffuse & reflect ambient light as well as diffuse back light. These have traditionally been used behind low-power LCD displays which are viewed using ambient light as well as backlight on demand.

Significantly enhances display qualities for many applications

Applications

- LCD reflectors

- Legacy systems

- Reflective targets

- Prototyping

- Modeling

- Ultra-bright color displays

- Outdoor / bright environment displays

- Military / aviation instrumentation

- 3D & holographic displays

Thicknesses

- 0.5mm

- 0.6mm

- 0.7mm

- 0.8mm

- 1.0mm

Size

- 380mm x 530mm is standard

- Please contact us to discuss standard and custom sheet size options.

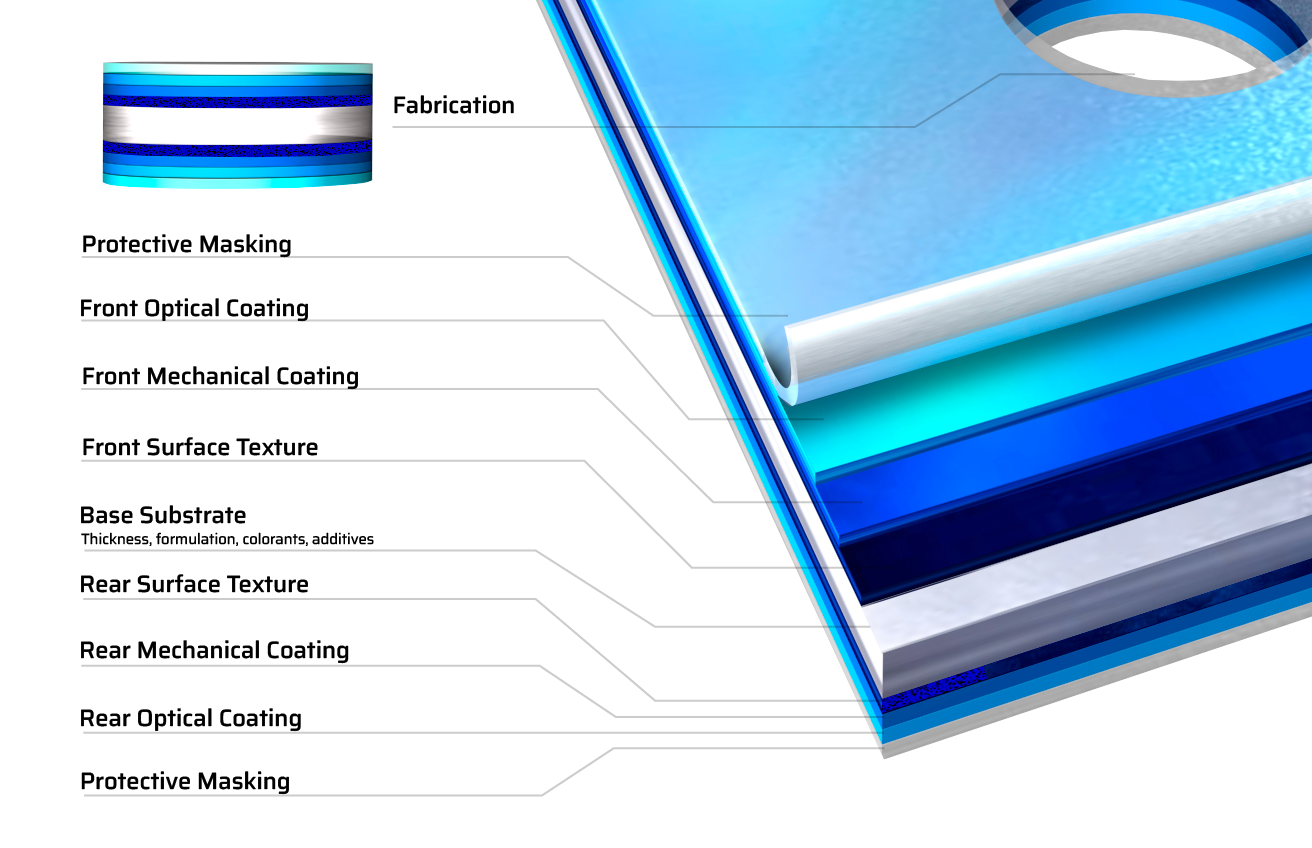

Customization

Custom sheets & parts to meet your application

Do you have a unique design requirement? We can help! Choose the thickness, formulation, additives, color dye/pigments, surface textures, surface coatings, and optical coatings for your custom material configuration, and if we don’t already have it in stock at our warehouse in New York, we can typically have it ready for you in 4-8 weeks. We can even fabricate the finished parts for you.

Available Colors/Shades

| GRADE | COLOR TONE | LIGHTNESS | TOTAL LIGHT |

|---|---|---|---|

| 501 000 | White | 45% | 73% |

| 505-4 000 | White | 61% | 54% |

| 801-1 000 | White | 64% | 39% |

| 502-1 000 | White | 75% | 34% |

| 503 000 | White | 80% | 24% |

| 505-1 000 | White | 81% | 19% |

| 705-1 000 | White | 76% | 19% |

| 503 BG-01 | Green | 47% | 8% |

| 505-4 BG-01 | Green | 39% | 27% |

| 503 GR-04 | Green | 58% | 13% |

| 505-4 GR-04 | Green | 50% | 34% |

| 503 GR-05 | Green | 65% | 16% |

| 505-4 GR-05 | Green | 56% | 42% |

| 503 GR-13 | Green | 71% | 19% |

| 505-4 GR-13 | Green | 58% | 46% |

| 503 BR-22 | Blue | 61% | 16% |

| 505-4 BR-22 | Blue | 51% | 40% |

| 503 G-100 | Gold | 76% | 22% |

| 505-4 G-100 | Gold | 59% | 52% |

| 503 YR-02 | Yellow | 75% | 23% |

| 505-4 YR-02 | Yellow | 60% | 52% |

| 503 FY-01 | Yellow | 88% | 26% |

| 505-4 FY-01 | Yellow | 70% | 57% |

| 503 FP-02 | Pink | 64% | 17% |

| 505-4 FP-02 | Pink | 53% | 43% |

| 503 OR-07 | Orange | 56% | 14% |

| 505-4 OR-07 | Orange | 48% | 39% |

Chemical Properties

| REAGENT | CHANGE OF APPEARANCE |

|---|---|

| Ethyl Alcohol (50%) | No Change |

| Isopropyl Alcohol | No Change |

| Soap Aqua Solution | No Change |

| Benzene | Swollen |

Optical Properties

| PROPERTY | METHOD | UNIT | VALUE |

|---|---|---|---|

| Heat Distortion Temperature | ASTM D-648 | °C | 110 |

| Maximum Recommended Continuous Temperature | °C | 80 | |

| Available with higher temperature ratings on request, 90-95ºC | |||

| Coefficient of Thermal Expansion | ASTM D-696 | cm/cm/°C | 7 x 10-5 |

| Pencil Hardness | 2H | ||

| Heat Resistance | 80°C x 100hr | No Change | |

| Cold Resistance | -40°C x 100hr | No Change | |

| Humidity Resistance | 60°C x 90% x 100hr | No Change | |

| Thermal Cycle | -40°C<->80°C (10 cycles) | No Change | |