CLAREX UV-Filtering Acrylic Sheets

Enhanced UV protection for sensitive applications.

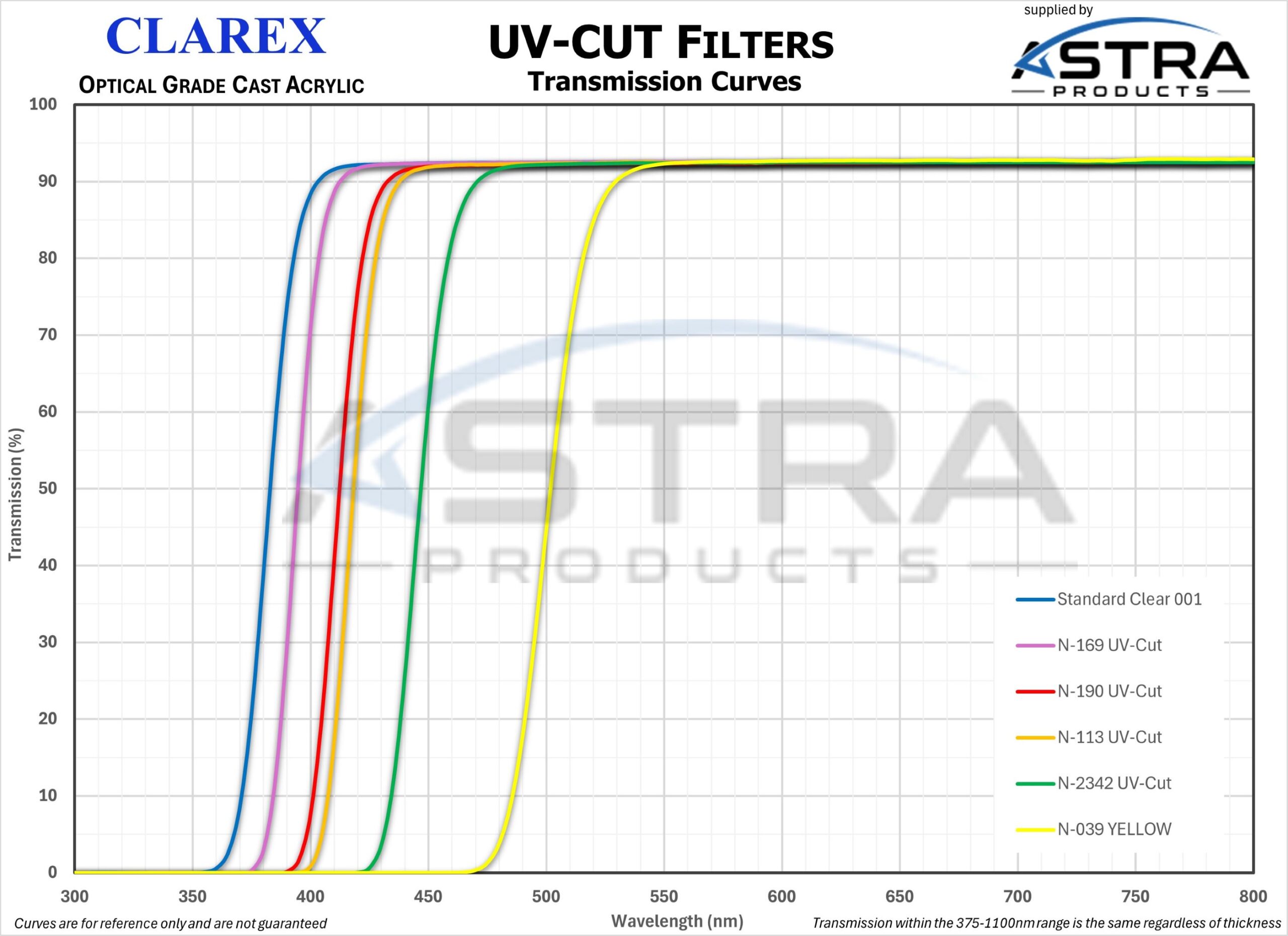

Standard CLAREX cast acrylic sheets include UV inhibitors that block wavelengths below 375nm; however, for applications requiring additional UV protection, CLAREX UV-Cut sheets are available with filtering options that extend up to 480nm. As the cutoff wavelength increases, the material takes on a yellow tint—most notably with grade N-039, which also functions as a true yellow filter.

Benefits of UV-Blocking Acrylic Filters & Sheets

- Outstanding Optical Clarity – High light transmission with crystal-clear visibility, ideal for displays and protective covers.

- No Birefringence – Eliminates double refraction, ensuring distortion-free performance under polarized light.

- Superior Weatherability – Resists yellowing, clouding, and degradation from long-term outdoor UV exposure.

- Surface Flexibility – Available in glossy for maximum clarity or non-glare to reduce reflections in bright environments.

- Hard-Coat Protection – Optional scratch- and chemical-resistant coating extends durability in demanding applications.

- UV Shielding – Blocks harmful ultraviolet rays, protecting sensitive materials and extending product life.

UV-Cut Filters are used in applications which are sensitive to UV light.

Common UV-Filtering Acrylic Applications

- Display cases and protective covers

- Outdoor signage and displays

- Optical filters

- Scientific equipment/instrumentation

- Sensor windows

Thickness Options

- 0.2mm

- 1.5mm

- 0.3mm

- 2.0mm

- 0.4mm

- 2.5mm

- 0.5mm

- 3.0mm

- 0.6mm

- 3.5mm

- 0.7mm

- 4.0mm

- 0.8mm

- 4.5mm

- 1.0mm

- 5.0mm

- 1.2mm

- Custom

UV-Blocking Acrylic Sheet Sizes

- Standard small sheet: 400 × 550 mm

- Standard large sheet: 1000 × 1000 mm

- Custom sizes: Maximum dimensions depend on application—contact us to discuss options

Example Transmission Curves for UV-Filtering Acrylic

Customization

Custom sheets & parts to meet the needs of your applications.

Build your own sheets! Do you have a unique design requirement that cannot be met with off-the-shelf acrylic sheets? The CLAREX sheets can be fully customized and produced in low volumes up to mass production. Choose the thickness, formulation, additives, color dye/pigments, surface textures, surface coatings, and optical coatings for your custom material configuration, and we can typically have it ready for you in 4-8 weeks. We can even fabricate the finished parts for you.

Physical & Chemical Properties of CLAREX UV-Cut Filters

| PROPERTY | METHOD | UNIT | UNCOATED | WITH HARD COAT |

|---|---|---|---|---|

| Specific Gravity | ASTM D-792 | 1.19 | 1.19 | |

| OPTICAL | ||||

| Refractive Index | ASTM D-542 | 1.49 | 1.49 (1.54) | |

| MECHANICAL | ||||

| Elongation | ASTM D-638 | % | 5 | 5 |

| Tensile Rupture Strength | ASTM D-638 | kg/cm2 | 750 | 650 |

| Flexural Rupture Strength | ASTM D-790 | kg/cm2 | 1200 | 800 |

| THERMAL | ||||

| Heat Distortion Temperature | ASTM D-648 | °C | 108 | 110 |

| Maxiumum Recommended continuous temperature | °C | 80 | 80 | |

| *Available with higher temperature ratings upon request, 90-95 °C | ||||

| Coefficient of Thermal Expansion | ASTM D-696 | cm/cm/ºC | 7 x 10-5 | 7 x 10-5 |

| Specific Heat | ASTM D-638 | cal/grºC | 0.3535 | 0.35 |

| DURABILITY | ||||

| Heat Resistance | 80ºC x 100hr | No Change | No Change | |

| Cold Resistance | -40ºC x 100hr | No Change | No Change | |

| Humidity Resistance | 60ºC x 90% x 100hr | No Change | No Change | |

| Thermal Cycle | -40ºC <> 80ºC (10 cycles) | No Change | No Change | |

| ELECTRICAL | ||||

| Surface Resistivity | w | 10^16 | 10^16 | |

| CHEMICAL | ||||

| Methyl Alcohol (50%) | No Change | No Change | ||

| Ethyl Alcohol (50%) | No Change | No Change | ||

| Soap Aqua Solution | No Change | No Change | ||

| Toluene | Dissolved | No Change | ||

| Acetone | Dissolved | No Change | ||

| Benzene | Swollen | No Change | ||

| Ethylene Dichloride | Dissolved | No Change | ||

| OTHER | ||||

| Pencil Hardness | 2H | >6H | ||

| Adhesion | K-5400 | 100/100 | ||

| FLAMMABILITY | ||||

| Fire Resistivity | UL standard | >=0.8mm Thickness | 94HB | 94HB |

How Does an Acrylic Sheet Block UV?

Acrylic sheets block UV by using special additives that absorb and filter out harmful ultraviolet rays before they can pass through. This built-in protection helps prevent yellowing, clouding, and material breakdown, while also shielding sensitive items behind the sheet from UV damage. As a result, UV-blocking acrylic is commonly used in applications such as display cases, protective covers, and instrumentation where clarity and long-term durability are essential.

Ready to Get Started with UV-Filtering Acrylic Sheets?

Whether you need standard sizes, custom fabrication, or a specialized formulation, our team can help configure CLAREX acrylic to meet your exact requirements.