Frequently Asked Questions

Everything you need to know about Clarex materials

We’ve gathered the most common questions about Clarex acrylic materials and our process to provide you with a comprehensive guide to our products and services. Whether you’re curious about where Clarex is manufactured, what makes it unique, or how to customize your order, we have the answers. Our goal is to help you understand why Clarex stands out for high-performance applications, from optical clarity to light diffusion and reflection control, so you can make informed decisions for your projects.

Where is the Clarex material made?

The Clarex material is made in Japan by Nitto Jushi Kogyo (NJK for short). Astra Products is the exclusive North American sales agent.

What makes Clarex so special?

The Clarex acrylic products are manufactured under strict process controls to ensure that the material is of the highest quality. That includes:

- 100% visual inspection of each sheet

- Molecular weight is approximately 4x that of extruded acrylic, and 2x commercial grade cast acrylic

- The ingredients used are very pure, so the material has maximum long path transmission (good for light guides) and no autofluorescence (good for microfluidics).

- There is no birefringence

- The mold sets used are highly polished, resulting in sheets with minimal surface roughness and wavefront distortion

Clarex acrylic can be cast all the way down to 0.1mm (0.004”) thick. - The hardcoat is acrylic based (won’t delaminate) and outdoor/UV safe, and does not change the optical properties of the material…..it is still optical grade.

- The factory has the unique capability to apply the hardcoat to the molded-in nonglare textured surface without filling in the texture. Other manufacturers need to add particles to their hardcoats in order to create a nonglare texture, which reduces the quality and the transmission of the nonglare texture.

- Clarex material can be made custom to your specifications in any qty you need. For instance, if you need a single sheet of a specific color of green acrylic, in 1.2mm thickness, with nonglare #1 texture on one side, and hardcoat on the opposite side, it’s no problem…..it’ll be ready in about 4 weeks!

How do the diffusers work?

The main line of diffusers, DR-IIIS and DR-IIIC, are comprised of cast acrylic with light scattering particles loaded in along with matte textures front and back. They are considered bulk diffusers, meaning they have no orientation, they scatter light in all directions. They are typically sold as pure white, so they do not have any color shift, however color matched diffusers are an option. The DR-III diffusers are available from 5% up to 93% transmission in 5% increments. And thicknesses range from 0.2 up to 2.0mm, although there are some minimum thickness restrictions for some of the transmission levels. The thickness and transmission are independent, so a 0.5mm 70% diffuser will perform the same as a 2.0mm 70% diffuser.

The higher the transmission, the lower the hiding power, and vice versa. So if you have an LED array and you are trying to hide the hot spots from the LEDs you can start with a high transmission diffuser and keep stepping down in transmission level until you get the uniformity you are looking for. Increasing the gap between the diffuser and the LED also helps. We’re happy to send out samples for your testing and evaluation. Many of our customers are able to increase the brightness of an OEM display (brightness enhancement) simply by swapping out the OEM diffuser and replacing it with a Clarex diffuser with higher transmission while maintaining the same OEM backlight uniformity.

How much light in transmitted/reflected by standard acrylic (PMMA)?

When light hits a piece of acrylic, a small percentage reflects off the front surface and a small percentage gets reflected off the rear surface. The rest is transmitted through the material. For standard clear acrylic It works out to be about 92% transmitted and 8% reflected (4% reflected off the front surface and 4% reflected off the back surface).

Is it possible to reduce the reflection?

Yes, it is possible to add an antireflection coating to one or both surfaces. The antireflection coating is typically applied as a vacuum deposition process.

Whereas an uncoated acrylic surface will typically reflect about 4% of incident light, an antireflection (AR) coated surface will reflect <1% of visible light. If the coating is applied to both sides of a clear acrylic sheet, the resulting transmission will increase from ~92% to ~98%, and the reflections would decrease from ~8% to ~2%. This reduction in reflections can make it possible to see a display under direct sunlight conditions and it can help to eliminate ghost imaging for a camera enclosure.

What are the drawbacks of anti-reflective coating?

The antireflection coating performs well and is sometimes essential to achieving acceptable performance in an application. However, there are drawbacks. One is cost. The coating is difficult to apply, requiring several layers applied within a vacuum chamber. Another drawback is with smudges. Any sort of fingerprint/smudge stands out on the coated surface, but due to the properties of the coating (oleophilic) the surface is very difficult to clean. For this reason, many of our antireflection coated sheets include an antifingerprint (oleophobic) coating on one side. The antifingerprint coating doesn’t eliminate the smudges, but it makes them much easier to clean off. The downside to the antismudge coating is that adhesives cannot bond to it well and it cannot be printed on. This must be taken into consideration when designing your product.

What is a nonglare (AKA antiglare) surface?

The antireflection coating performs well and is sometimes essential to achieving acceptable performance in an application. However, there are drawbacks. One is cost. The coating is difficult to apply, requiring several layers applied within a vacuum chamber. Another drawback is with smudges. Any sort of fingerprint/smudge stands out on the coated surface, but due to the properties of the coating (oleophilic) the surface is very difficult to clean. For this reason, many of our antireflection coated sheets include an antifingerprint (oleophobic) coating on one side. The antifingerprint coating doesn’t eliminate the smudges, but it makes them much easier to clean off. The downside to the antismudge coating is that adhesives cannot bond to it well and it cannot be printed on. This must be taken into consideration when designing your product.

What is the difference between antireflection coating and nonglare texture?

The antireflection coating physically reduces the amount of light that is reflected off of the surface it is applied to. The nonglare textures do not change the amount of light reflected off of a surface, instead they diffuse the light so that it is not as distracting to the viewer. It is possible to combine antireflection coating with nonglare texture.

If you have an outdoor display with bad reflections, can you put an antireflection coated filter in front of it to reduce reflection?

Unfortunately it’s not that easy.

You can think of the antireflection coated materials as being almost “invisible”. If your outdoor display has bad reflections and you put an “invisible” filter in front of it, you will not reduce the amount of reflections coming off of the original display. Instead you must address the source of the reflections, which in this case may be the front surface of the LCD panel. You may be able to source the LCD from the OEM with an antireflection coating applied to the front. Another option is to optically bond an antireflection coated material to the front surface of the display.

Do the antireflection coatings work in the near infrared and ultraviolet ranges?

Sort of. The standard antireflection coatings are designed to minimize the reflections in the visible range. The side effect of that coating design is that it actually increases the reflections in the near infrared (NIR) range. But the factory is able to custom tune the antireflection coatings for specific applications. One option is to design the coating for minimum reflections across the NIR range. In that case it will create a lot of reflection in the visible range…..the filters will look like they have a partial mirror coating. If you only care about NIR transmission, then it’s no problem. But if you need to minimize both visible and NIR reflections, the factory could custom tune a coating to target the visible range and a specific NIR wavelength. The same goes for the UV range.

How does the color matching work?

You send us either the specs for the color you need, or a sample of it. The factory will first check through their extensive portfolio of colors they have made in the past to see if they already have a pigment formulation for it. If so, we’re good to go and could make you whatever you need in that specific color. If they don’t have a match, they will develop the required formulation for a nominal fee (usually a few hundred dollars) and from then on you can order your custom color material as needed.

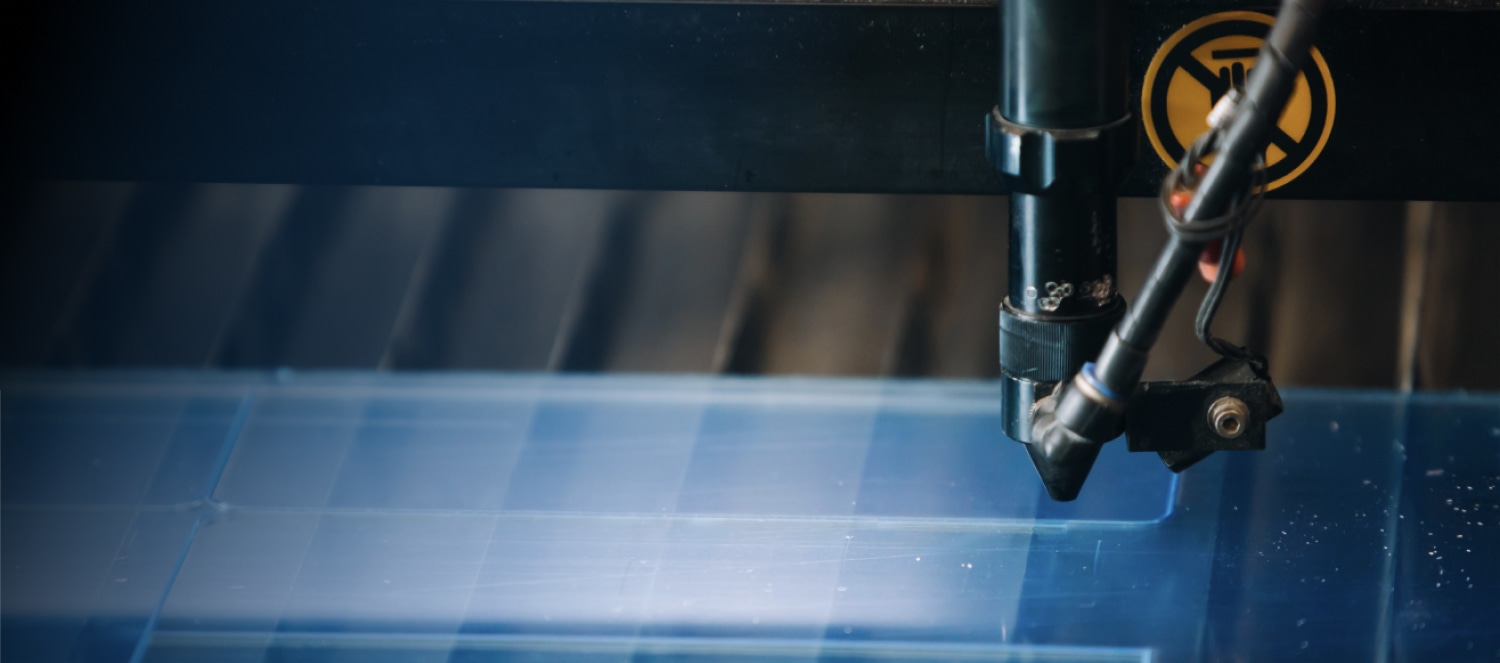

How do you recommend fabricating the Clarex materials?

All of the Clarex acrylic products are cast acrylic (PMMA), and fabricate like any other cast acrylic. They can be scored and snapped like glass, laser cut with CO2 lasers, machined using tooling designed for hard plastic, saw cut using blades designed for hard plastic, and thermoformed (uncoated materials only). You cannot die cut, punch, or use scissors on the material. And remember, we fabricate finished parts here in NY as well as in the factory in Japan.

Can you print on it?

The uncoated surfaces will print similar to commercial grade cast acrylic. It is possible to print on the hardcoated surfaces, but it is not easy to do. We have some ink suggestions for printing on the hardcoat. Give a call/email to discuss further.

How can I place an order?

There are many configurations of material possible, so it is best to give us a call or email first to discuss your application so that we can be sure you’re getting the best material for your project. We do not offer an online shopping cart for this reason. Orders can be sent in by email or fax, or could be taken verbally over the phone. We accept credit cards, ACH, wires, and bank checks for payments. Note: all bank checks must come from a US bank.

What are lead times?

If we have the material you need in stock, we can usually have it shipped out the day after we receive an order. For laser cut parts from stock material it’s typically <1 week. For cnc routed parts and parts with adhesive, it’s usually 2-3 week lead times if we have the material. If the material needs to be made custom, whether you are getting full sheets or finished parts, the lead time is typically 4-6 weeks.

Are there minimum order quantities?

Not really. If we have material in stock, the MOQ is just a single sheet. If you are looking for finished parts we will often sell less than a full sheet’s worth of parts. If you need custom material made to order, the MOQ is still typically just 1 sheet. But, please understand that all the setup costs get rolled into that one sheet, so it’s not going to be cheap. In some cases, such as custom antireflection coatings, there will be larger, but reasonable, MOQs.