CLAREX Near-Infrared Acrylic (NIR)

Optical grade longpass NIR filters available in a variety of configurations to meet your needs.

CLAREX Acrylic NIR Filters transmit near infrared (NIR) light and block/absorb visible light. There are several types of NIR filters to choose from with cut-ins from 670nm to 910nm.

For applications where reflections/glare are causing issues, we can supply the NIR sheets with anti-reflection coatings designed specifically for NIR applications. Click here for more info.

The standard NIR filters block almost all visible light. There is less than 1% visible light transmission. However, sometimes that isn’t enough in the case of super bright light sources. If necessary, we can increase the density of the NIR pigments used in the sheet to further reduce the amount of visible light leaking through.

Benefits

- Transmit NIR light and block/absorb visible

- Optical Grade Cast Acrylic

- No Birefringence

- Low wavefront distortion

- Excellent weatherability and chemical resistance

- Available smooth surface or anti-glare surface

- Available with scratch/chemical resistant coat

- Available with custom-tuned anti-reflection coating

Applications

- Instrumentation

- Sensors

- Communications and Optical Devices

- LIDAR filters

- Machine Vision

- Time of Flight Sensors

- Covert Imaging & Illumination

Thicknesses

- 0.5mm

- 0.6mm

- 0.7mm

- 0.8mm

- 1.0mm

- 1.2mm

- 1.5mm

- 2.0mm

- 2.5mm

- 3.0mm

- 3.5mm

- 4.0mm

- 4.5mm

- 5.0mm

- Custom

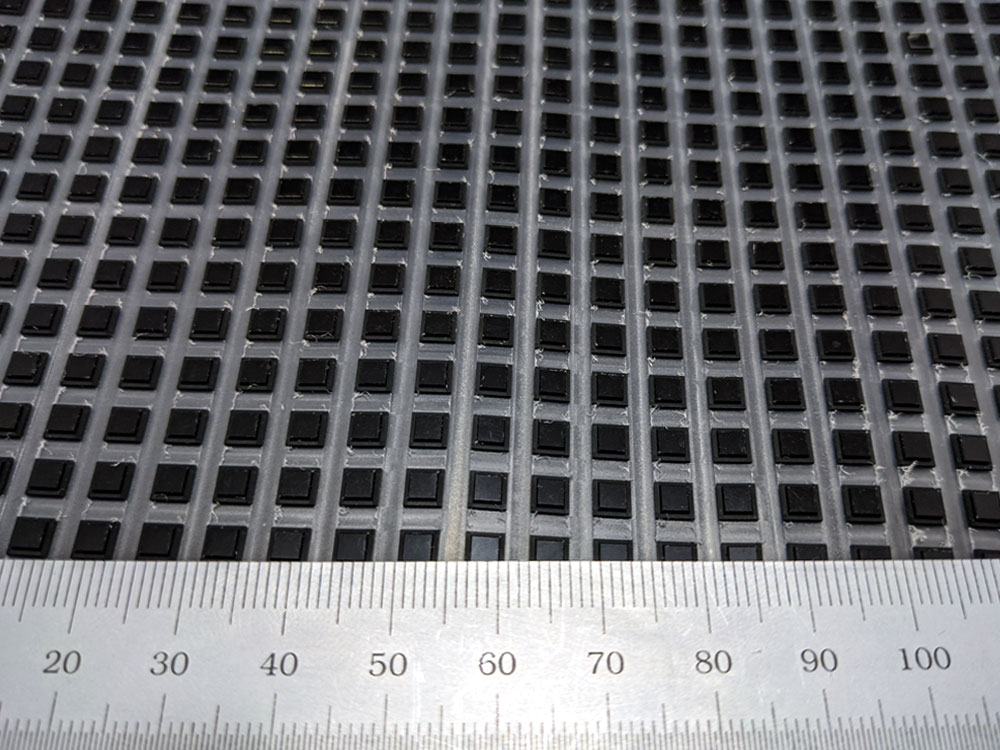

Size

- 400mm x 550mm standard

- Custom sizes available upon request

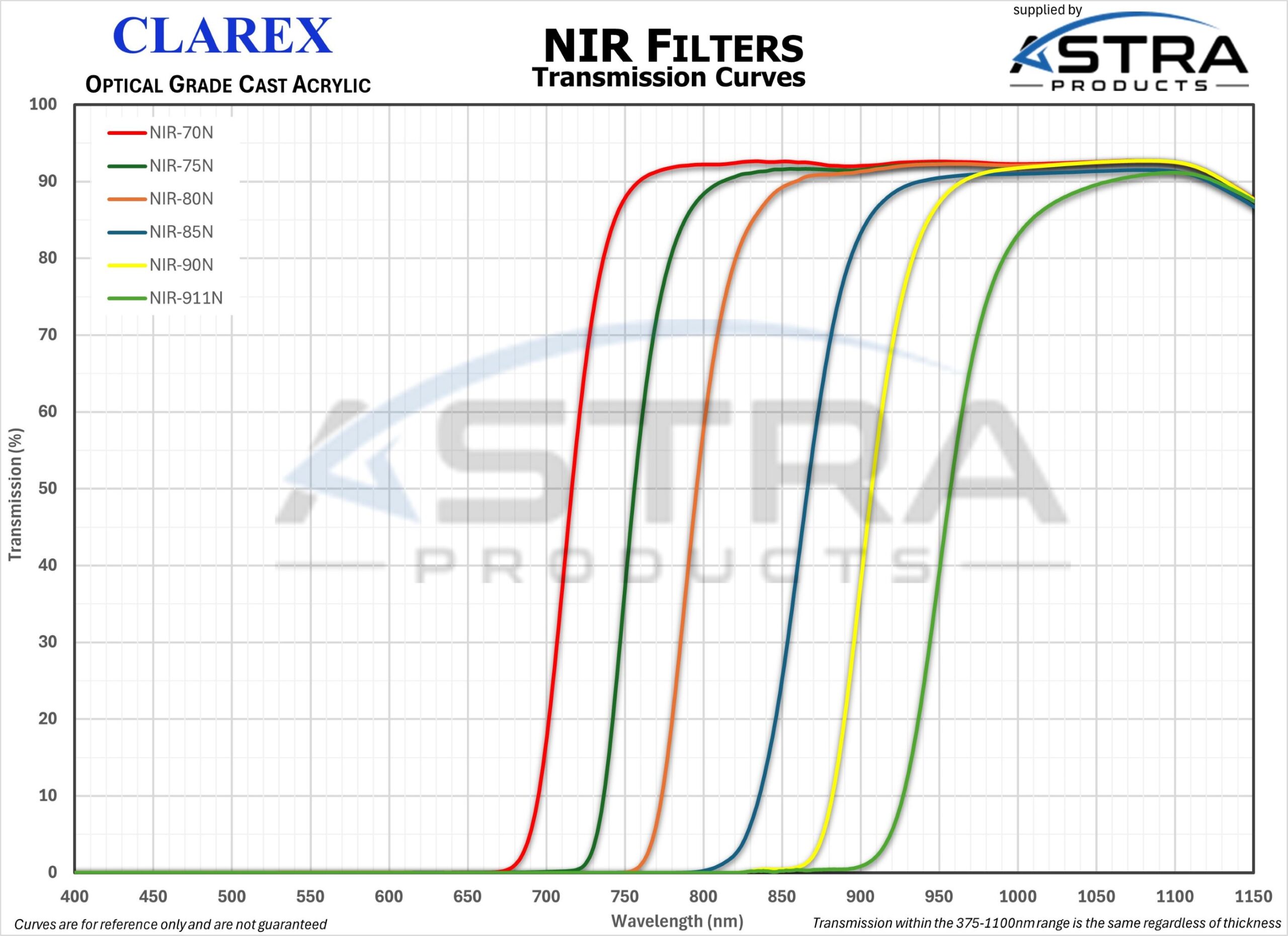

Transmission Curves

| Type No. | Near Infrared transmission |

|---|---|

| NIR-70N | Transmit from 670nm |

| NIR-75N | Transmit from 730nm |

| NIR-80N | Transmit from 760nm |

| NIR-85N | Transmit from 810nm |

| NIR-90N | Transmit from 860nm |

| NIR-911N | Transmit from 910nm |

Physical & Chemical Properties of CLAREX Near-Infrared (NIR) Filters

| Property | Method | Unit | UNCOATED | with HARD-COAT |

|---|---|---|---|---|

| Specific Gravity | ASTM D-792 | 1.19 | 1.19 | |

| Optical | ||||

| Refractive Index | ASTM D-542 | 1.49 | 1.49 (1.54) | |

| Mechanical | ||||

| Elongation | ASTM D-638 | % | 5 | 5 |

| Tensile Rupture Strength | ASTM D-638 | kg/cm2 | 750 | 650 |

| Flexural Rupture Strength | ASTM D-790 | kg/cm2 | 1200 | 800 |

| Thermal | ||||

| Heat Distortion Temperature | °C | 110 | 110 | |

| Maximum Recommended Continuous Temperature | °C | 80 | 80 | |

| Available with higher temperature ratings upon request, 90-95 °C | ||||

| Durability | ||||

| Heat Resistance | 80ºC x 100hr | No Change | No Change | |

| Cold Resistance | -40ºC x 100hr | No Change | No Change | |

| Humidity Resistance | 60ºC x 90% x 100hr | No Change | No Change | |

| Thermal Cycle | -40ºC <> 80ºC (10 cycles) | No Change | No Change | |

| Electrical | ||||

| Surface Resistivity | w | 10^16 | 10^16 | |

| Chemical | ||||

| Methyl Alcohol (50%) | No Change | No Change | ||

| Ethyl Alcohol (50%) | No Change | No Change | ||

| Soap Aqua Solution | No Change | No Change | ||

| Toluene | Dissolved | No Change | ||

| Acetone | Dissolved | No Change | ||

| Benzene | Swollen | No Change | ||

| Ethylene Dichloride | Dissolved | No Change | ||

| Other | ||||

| Pencil Hardness | 2H | 6~8H | ||

| Adhesion | K-5400 | 100/100 | ||

| Flammability | ||||

| Fire Resistivity | UL standard | >=0.8mm Thickness | 94HB | 94HB |