CLAREX Textured, Non-Glare Acrylic Sheets (NG)

Optimizes display readability by diffusing reflections.

Non-Glare Texture is also commonly referred to as Anti-Glare, AG, & Reduced-Glare. The CLAREX Non-Glare (AG) Textures are available from low to high gloss levels, and have been specifically developed for different applications. The medium gloss levels (30-70) are most common and generally used in front of flat panel displays to help eliminate the glare from a bright environment. The higher gloss (>70) levels are useful if there is a large gap between the display and the Non-Glare filter. The highest gloss levels (90+) can be used to eliminate Newton Rings without creating much haze. And the lowest gloss textures (<10) are used for light diffusion and aesthetics.

The Non-Glare textures are cast into the sheets. They are not coatings-based. So the textures are controlled and repeatable. And CLAREX is unique in that the factory is able to apply their standard hard-coating (6-8H Pencil Hardness) to the non-glare surfaces without filling in the texture.

Non-Glare surfaces could be added to one or both sides, and don’t necessarily have to match.

Note: If you hold one of these Non-Glare filters up and look through it, it will appear hazy. That haze goes away as the gap between the Non-Glare filter and the image behind it is reduced, so it works great directly in front of a display. However, it is not suitable for use in front of a camera or other imaging/sensor application. If reflections are causing you issues in your imaging application, check out the Anti-Reflection coated sheets.

Benefits

- Prevents direct reflection of light

- Enhances clarity of letters, figures, images

- Excellent optical characteristics

- No double refraction

- Reduce/eliminate Newton Ring issues

- Excellent weatherability

- Transmission and color can be matched to any display.

- Available with scratch-resistant coating as well as optical coatings

Applications

- Protective Windows/Panels

- Flat Panel Displays

- Newton Ring Elimination

- Diffusion

Thicknesses

- 0.5mm

- 0.6mm

- 0.7mm

- 0.8mm

- 1.0mm

- 1.2mm

- 1.5mm

- 2.0mm

- 2.5mm

- 3.0mm

- 3.5mm

- 4.0mm

- 4.5mm

- 5.0mm

- Custom

Sizes

- 400 x 550mm Standard sheet size

- Larger and custom sizes available in some cases

Customization

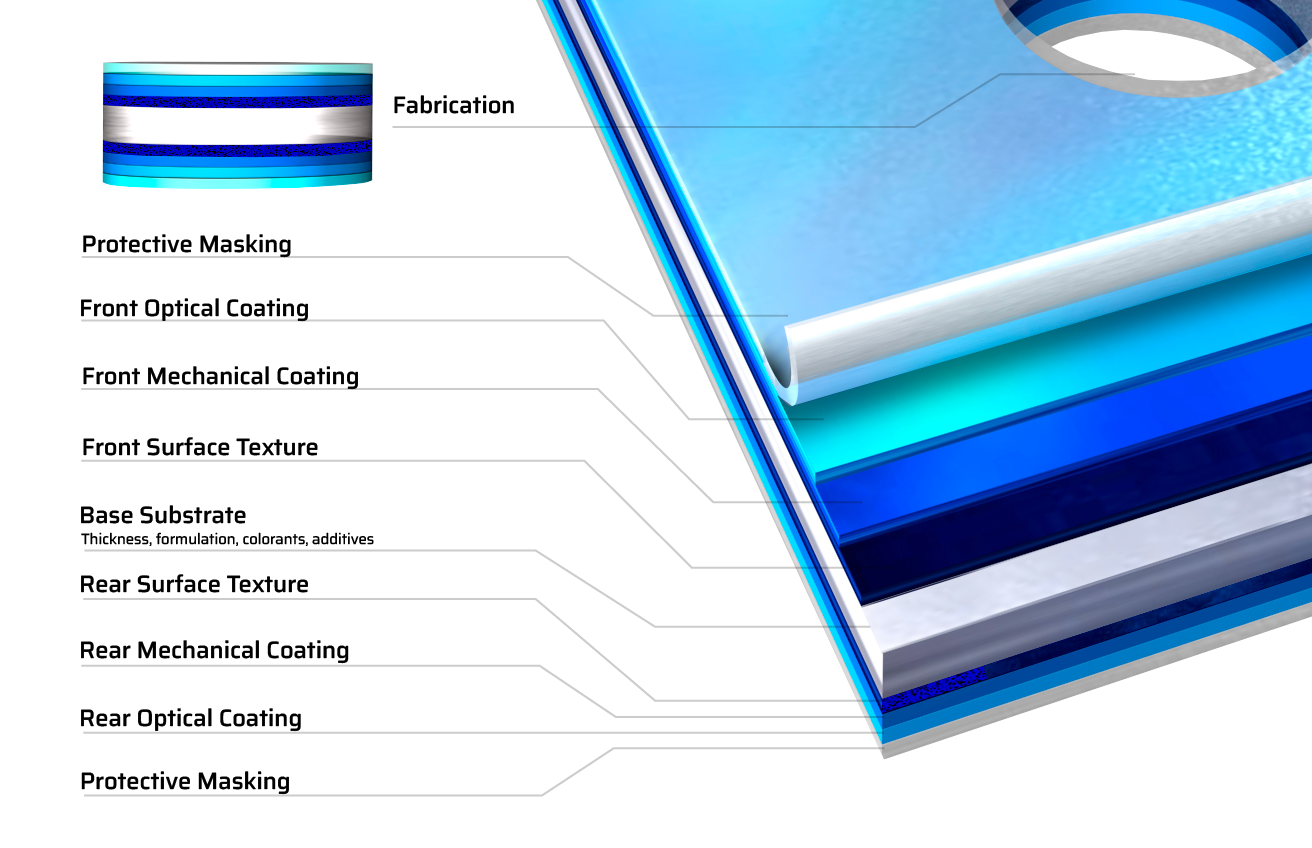

Custom sheets & parts to meet your application

Do you have a unique design requirement? We can help! Choose the thickness, formulation, additives, color dye/pigments, surface textures, surface coatings, and optical coatings for your custom material configuration, and if we don’t already have it in stock at our warehouse in New York, we can typically have it ready for you in 4-8 weeks. We can even fabricate the finished parts for you.

Non-Glare Textures

| Non-Glare Texture | Total Light Transmittance (clear sheet) | Haze (%) | Gloss Value |

|---|---|---|---|

| Glossy (no texture) | 93% | 0.1 | 118 |

| SM30 | 89% | 21 | 36 |

| SM50 | 89% | 10 | 59 |

| SM70 | 90% | 5 | 80 |

| SM90 | 90% | 3 | 102 |

| NG#1* | 92% | 2.0 | 55 |

| NG#2* | 90% | 6.0 | 35 |

| NG#3 (for diffusion) | 97% | 86 | 2 |

| NG#9* | 92% | 1.0 | 78 |

| EX20* | 92% | 4.0 | 57 |

| EX30* | 91% | 7 | 45 |

| EX70* | 92% | 3.0 | 72 |

Properties

| Property | Method | Unit | UNCOATED | with HARD COAT |

|---|---|---|---|---|

| Specific Gravity | ASTM D-792 | 1.19 | 1.19 | |

| Optical | ||||

| Refractive Index | ASTM D-542 | 1.49 | 1.49 (1.54) | |

| Mechanical | ||||

| Elongation | ASTM D-638 | % | 5 | 5 |

| Tensile Rupture Strength | ASTM D-638 | kg/cm2 | 750 | 650 |

| Flexural Rupture Strength | ASTM D-790 | kg/cm2 | 1200 | 800 |

| Thermal | ||||

| Heat Distortion Temperature | °C | 108 | 110 | |

| Maximum Recommended Continuous Temperature | °C | 80 | 80 | |

| Available with higher temperature ratings upon request, 90-95 °C | ||||

| Durability | ||||

| Heat Resistance | 80ºC x 100hr | No Change | No Change | |

| Cold Resistance | -40ºC x 100hr | No Change | No Change | |

| Humidity Resistance | 60ºC x 90% x 100hr | No Change | No Change | |

| Thermal Cycle | -40ºC <> 80ºC (10 cycles) | No Change | No Change | |

| Electrical | ||||

| Surface Resistivity | w | 10^16 | 10^16 | |

| Chemical | ||||

| Methyl Alcohol (50%) | No Change | No Change | ||

| Ethyl Alcohol (50%) | No Change | No Change | ||

| Soap Aqua Solution | No Change | No Change | ||

| Toluene | Dissolved | No Change | ||

| Acetone | Dissolved | No Change | ||

| Benzene | Swollen | No Change | ||

| Ethylene Dichloride | Dissolved | No Change | ||

| Other | ||||

| Pencil Hardness | 2H | >6H | ||

| Adhesion | K-5400 | 100/100 | ||

| Flammability | ||||

| Fire Resistivity | UL standard | >=0.8mm Thickness | 94HB | 94HB |