CLAREX Optical-Grade Cell-Cast Thin Acrylic Sheets

The foundational base substrate for nearly every product we offer.

CLAREX acrylic (also known as PMMA or poly-methyl methacrylate) is engineered for unsurpassed optical clarity and consistency, while offering a wide range of customizable features. Produced using a specialized batch cell-cast process, these sheets deliver the highest-quality optical-grade acrylic available on the market. This same process also allows for full customization—from low-volume specialty runs to large-scale production—without compromising performance.

Benefits of Cell-Cast Thin Acrylic Sheets

- Ultra-Smooth Surfaces – Highly polished mold sets create surfaces with roughness less than 0.02µ for exceptional optical clarity.

- Defect-Free Quality – Every sheet is 100% visually inspected for consistency and precision.

- Weather & Chemical Resistant – Reliable performance in challenging environments.

- Low Wavefront Distortion – Maintains optical accuracy for demanding applications.

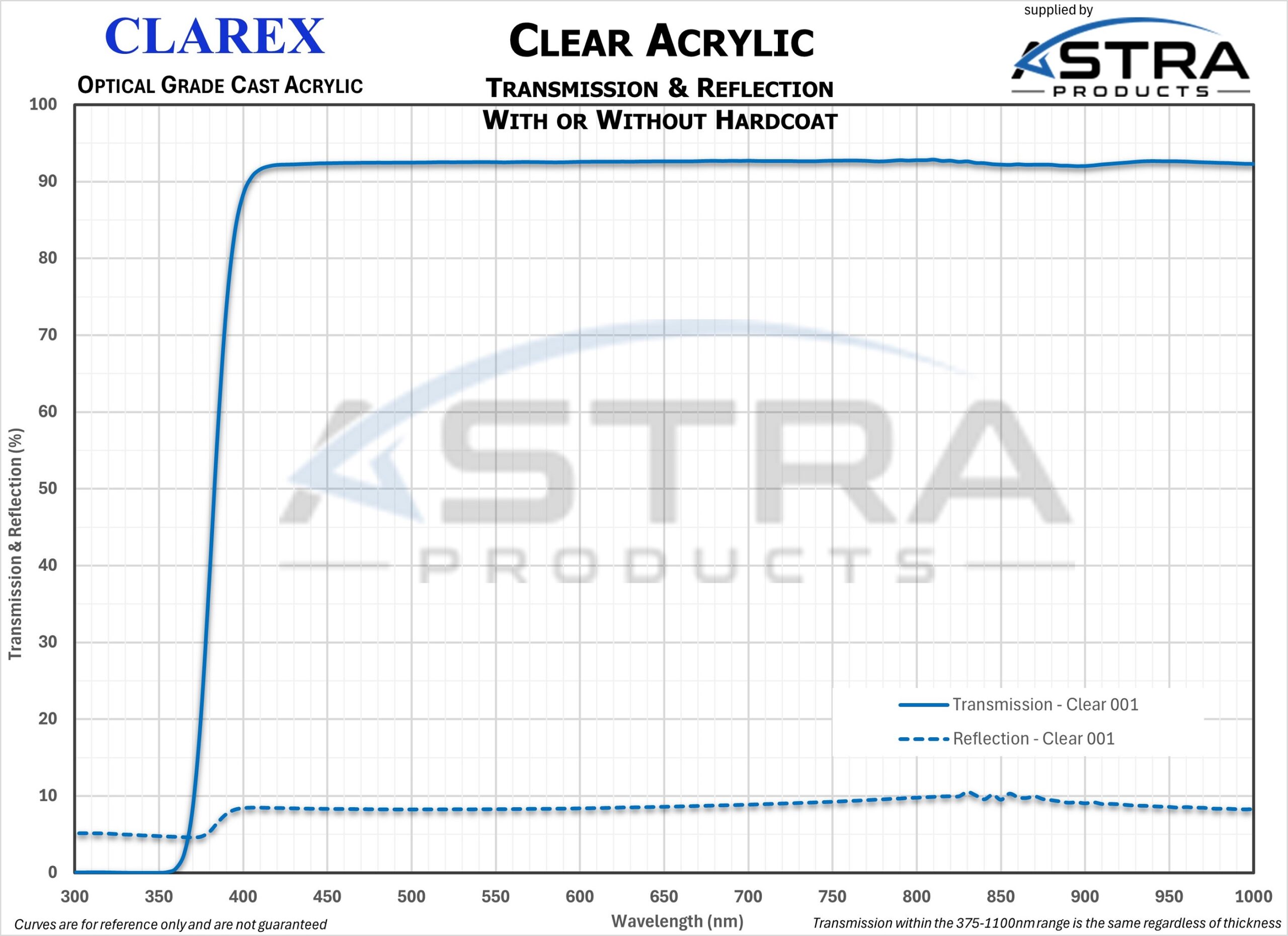

- High Light Transmission – Achieves up to 92% transmission in clear sheets without an anti-reflective coating.

- Isotropic Transmission – No birefringence or double refraction, ensuring polarized light passes cleanly.

- No Autofluorescence – Pure liquid monomer formulation prevents unwanted glow under UV or laser light.

- High Molecular Weight – 2+ million for strength, stability, and durability.

Common Thin Acrylic Sheet Applications

- LCD protective windows

- Camera and lens covers

- Sensor and light filters

- Architectural models

- Microfluidics substrate

- Prototyping and product development

Thickness Options

- 0.2mm

- 0.25mm

- 0.3mm

- 0.35mm

- 0.4mm

- 0.5mm

- 0.6mm

- 0.7mm

- 0.8mm

- 1.0mm

- 1.2mm

- 1.5mm

- 2.0mm

- 2.5mm

- 3.0mm

- 3.5mm

- 4.0mm

- 4.5mm

- 5.0mm

- Custom

Cell-Cast Acrylic Sheet Sizes

- Standard small sheet: 400 × 550 mm

- Standard large sheet: 1000 × 1000 mm

- Custom sizes: Maximum dimensions depend on application—contact us to discuss options

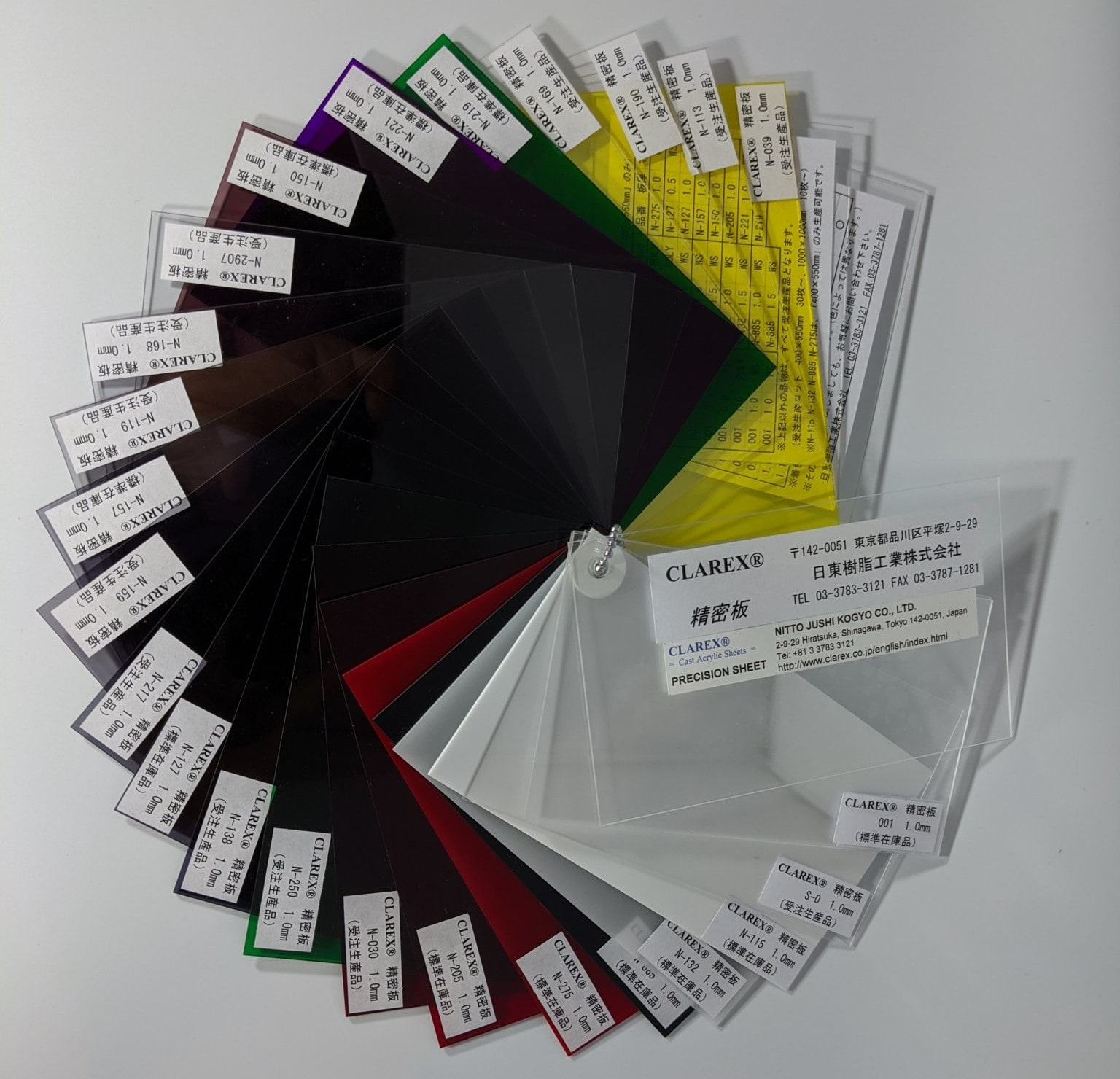

Color Options

- Colors are typically transparent, however a wide range of transparent, translucent, and opaque colors are available

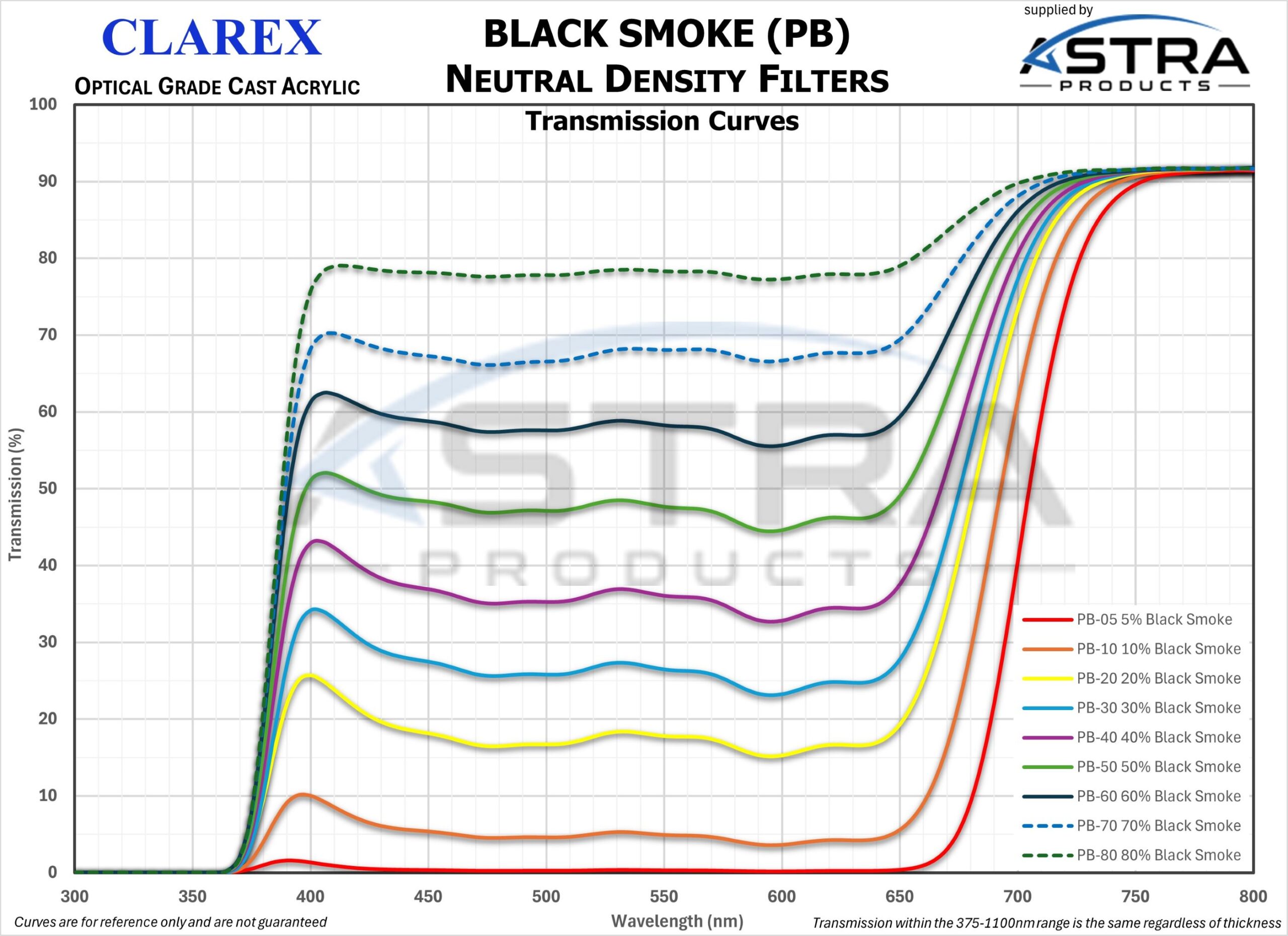

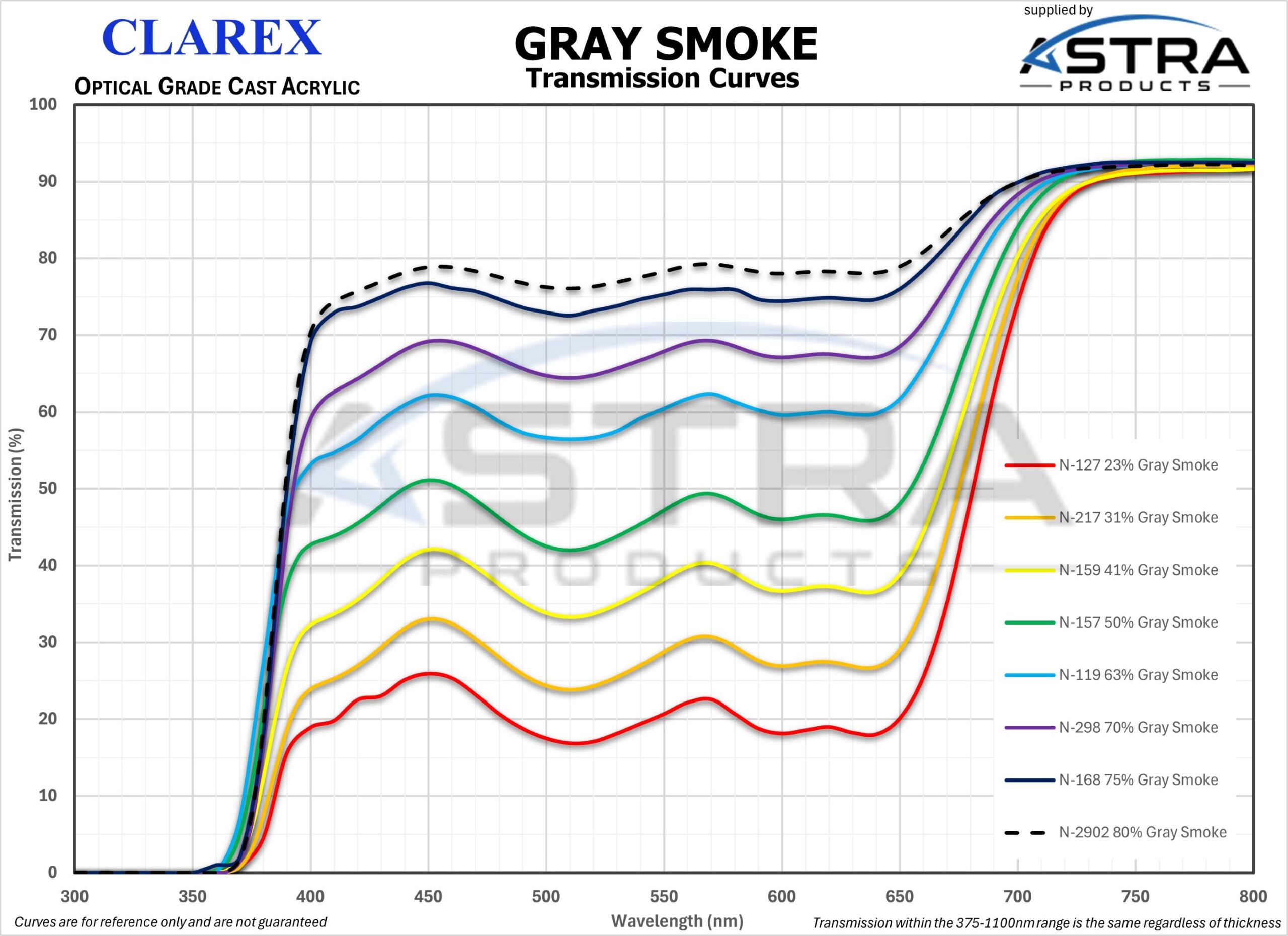

- Neutral density (smoke) and other specialty tints offered

- Colors available from 0.5 mm thickness and up

- Custom color-matching is available if your color isn’t already in our color portfolio

Coating Options

- Optical-grade hard coat for scratch and chemical resistance

- Antibacterial hard-coat

- Anti-reflective (AR) coatings

- Mirror coatings

- Additional specialty coatings available

Surface Finishes

- Non-glare textures can be molded in during casting (not a coating).

- Multiple texture options with varying gloss levels available

- Available one or both sides in any combination

Special Formulations

- High-temperature

- UV transmit (UVT)

- Added UV-blocking protection

- Low moisture absorption

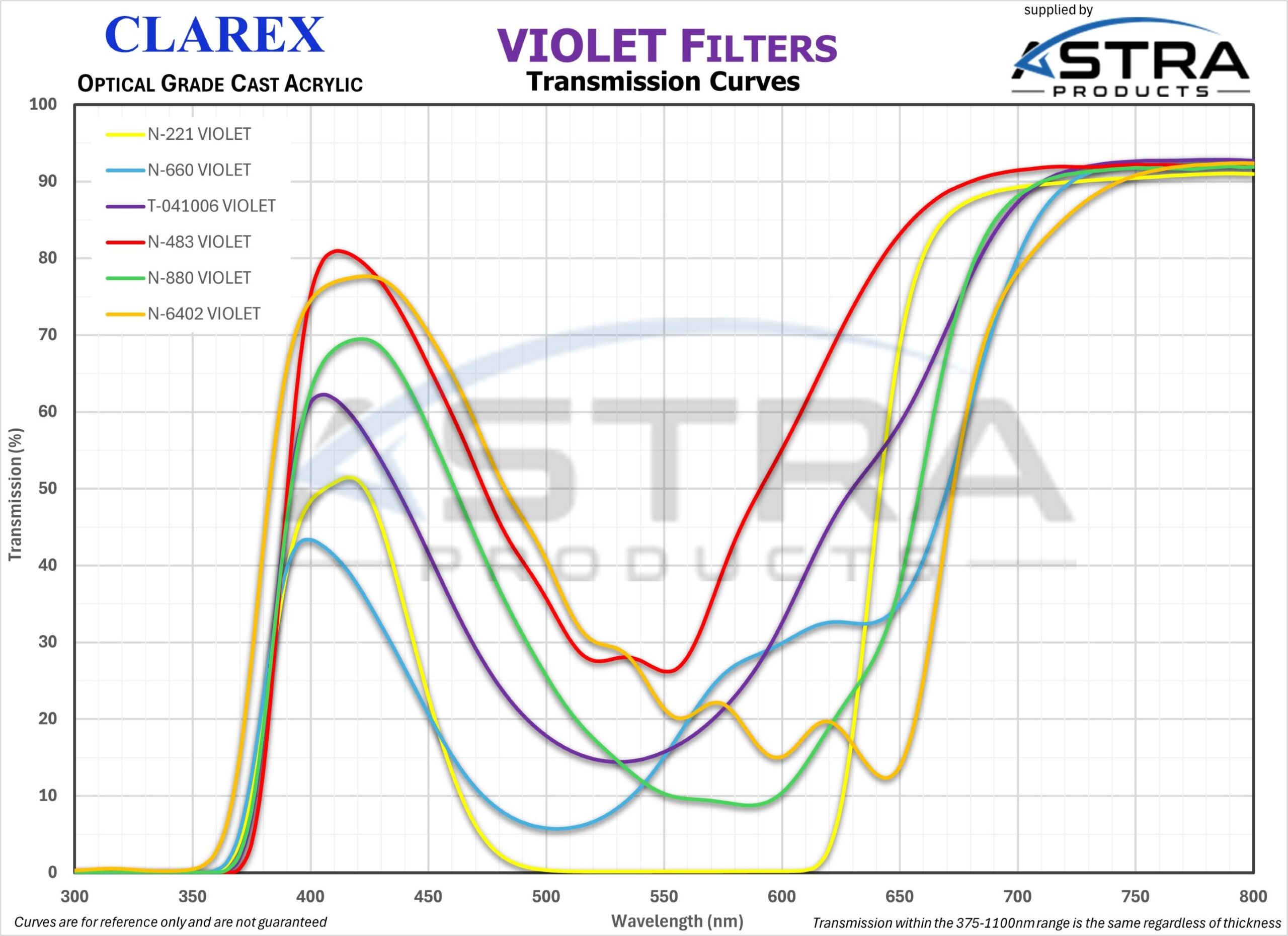

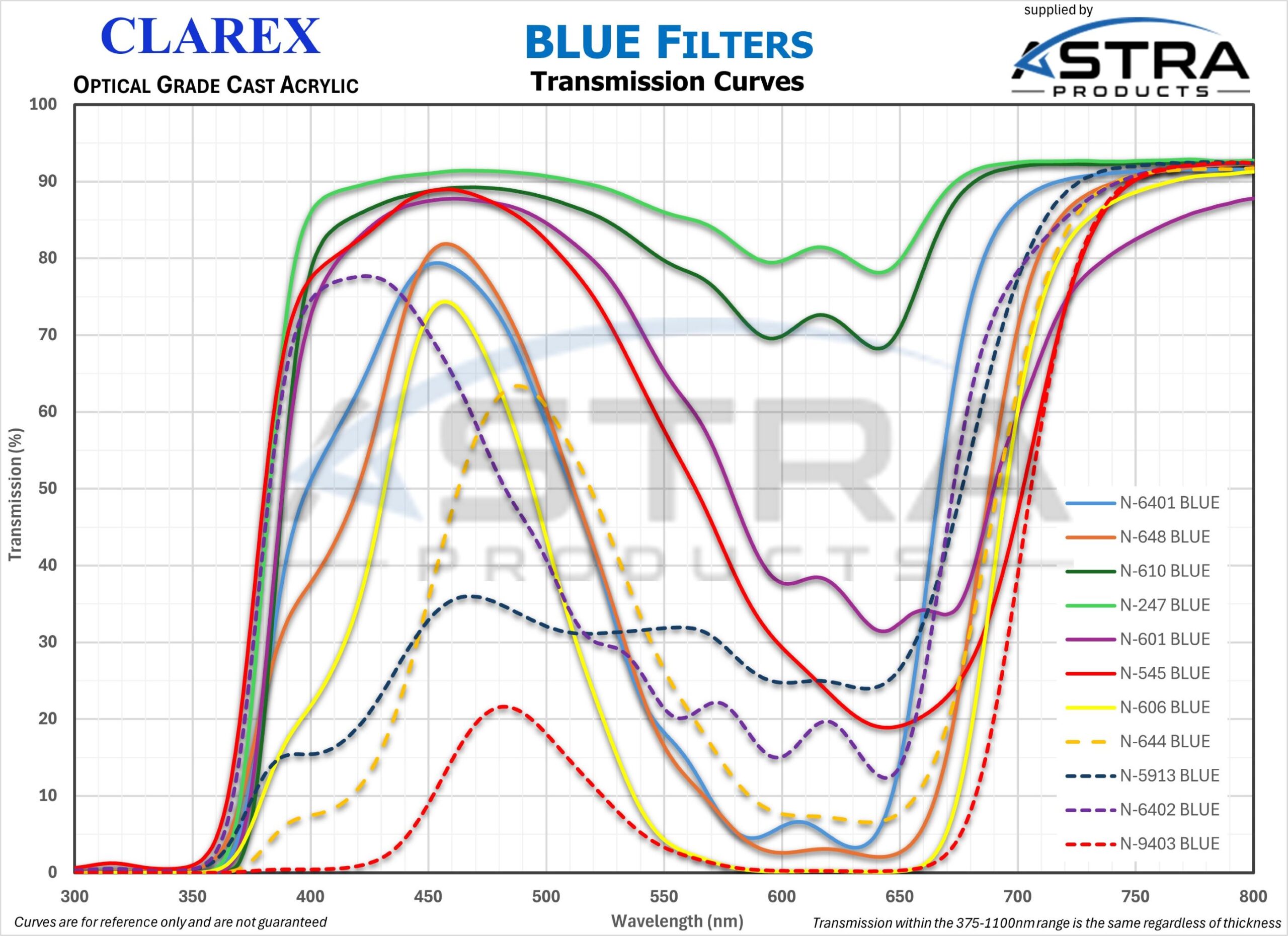

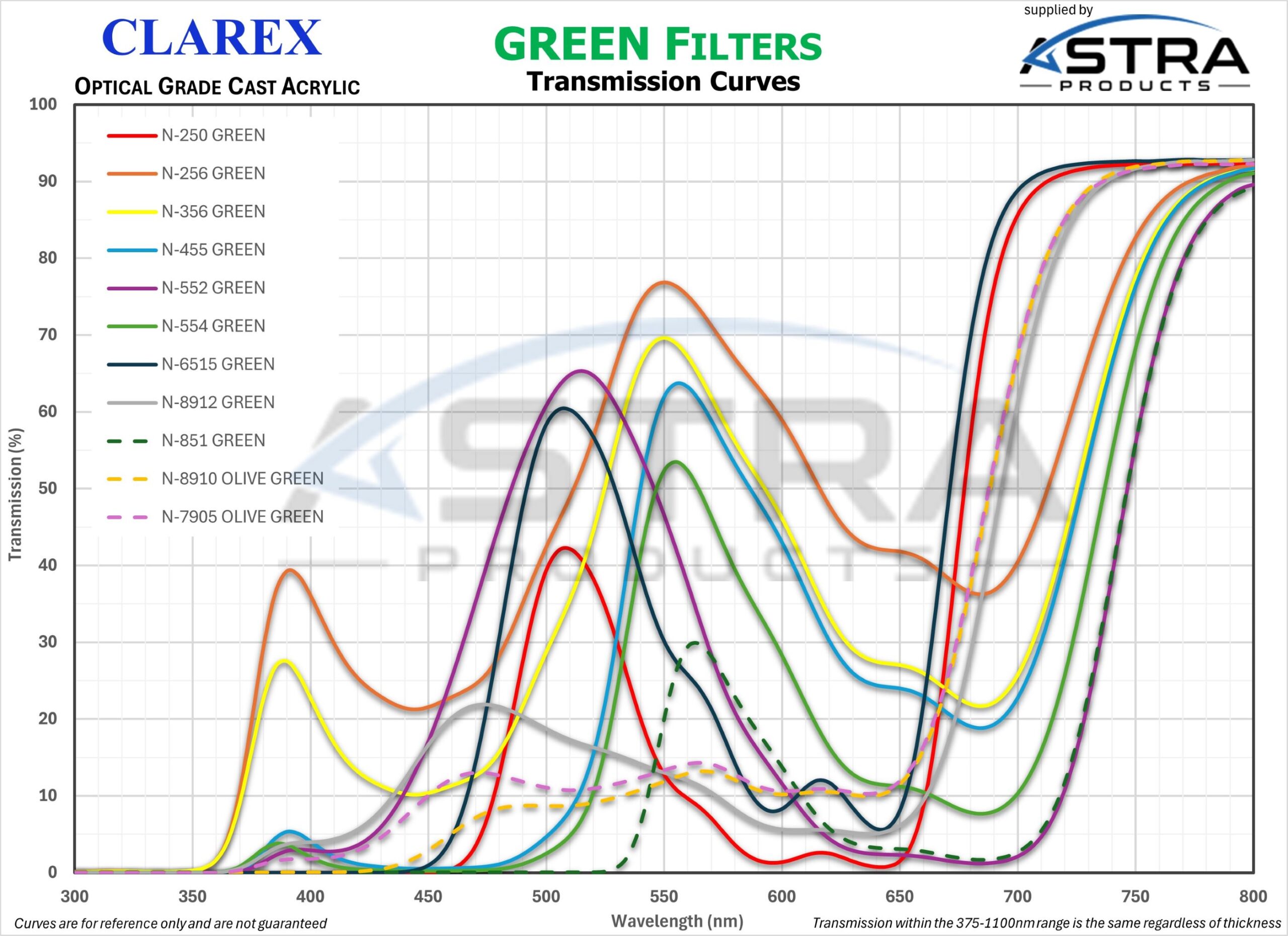

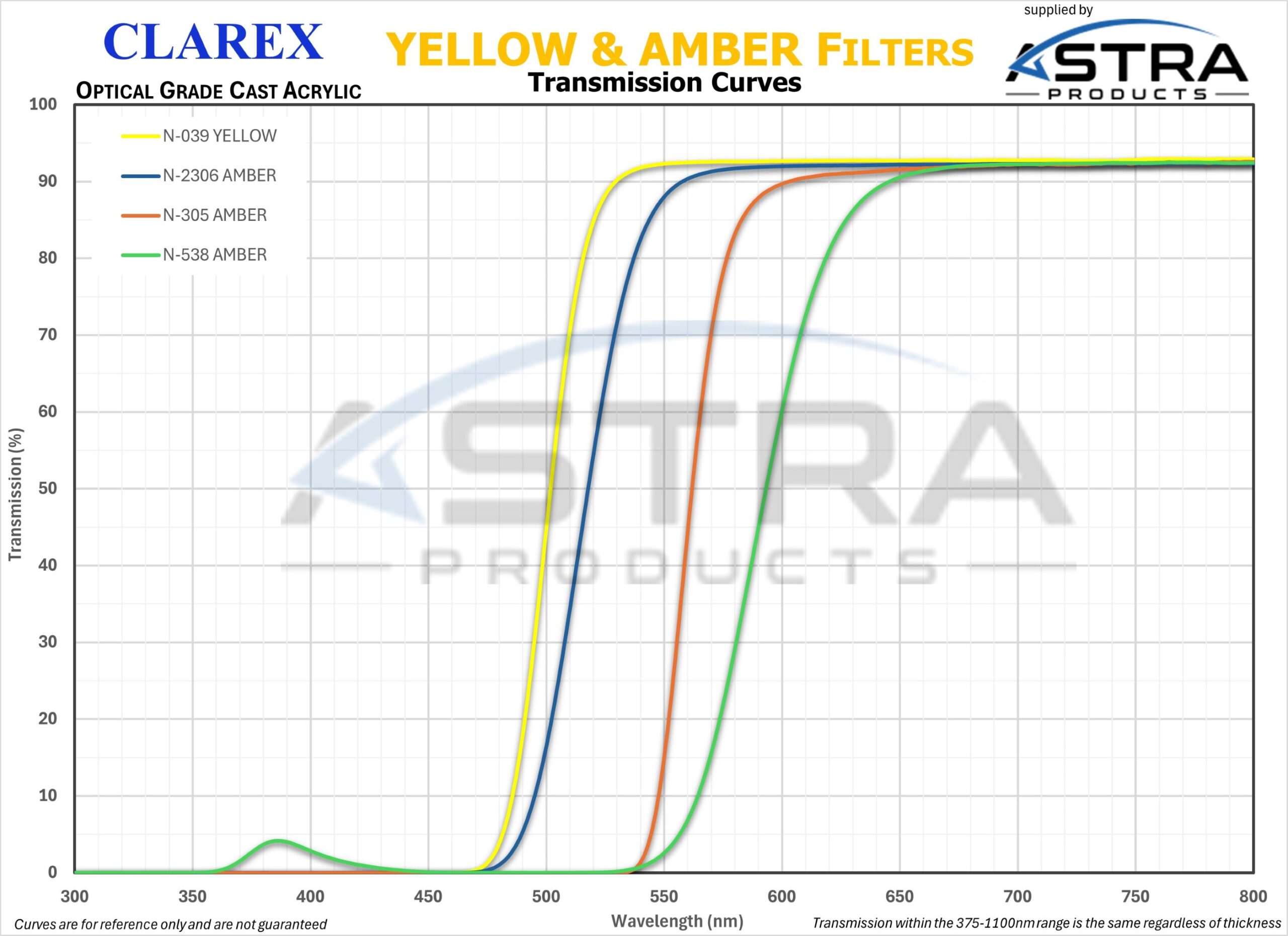

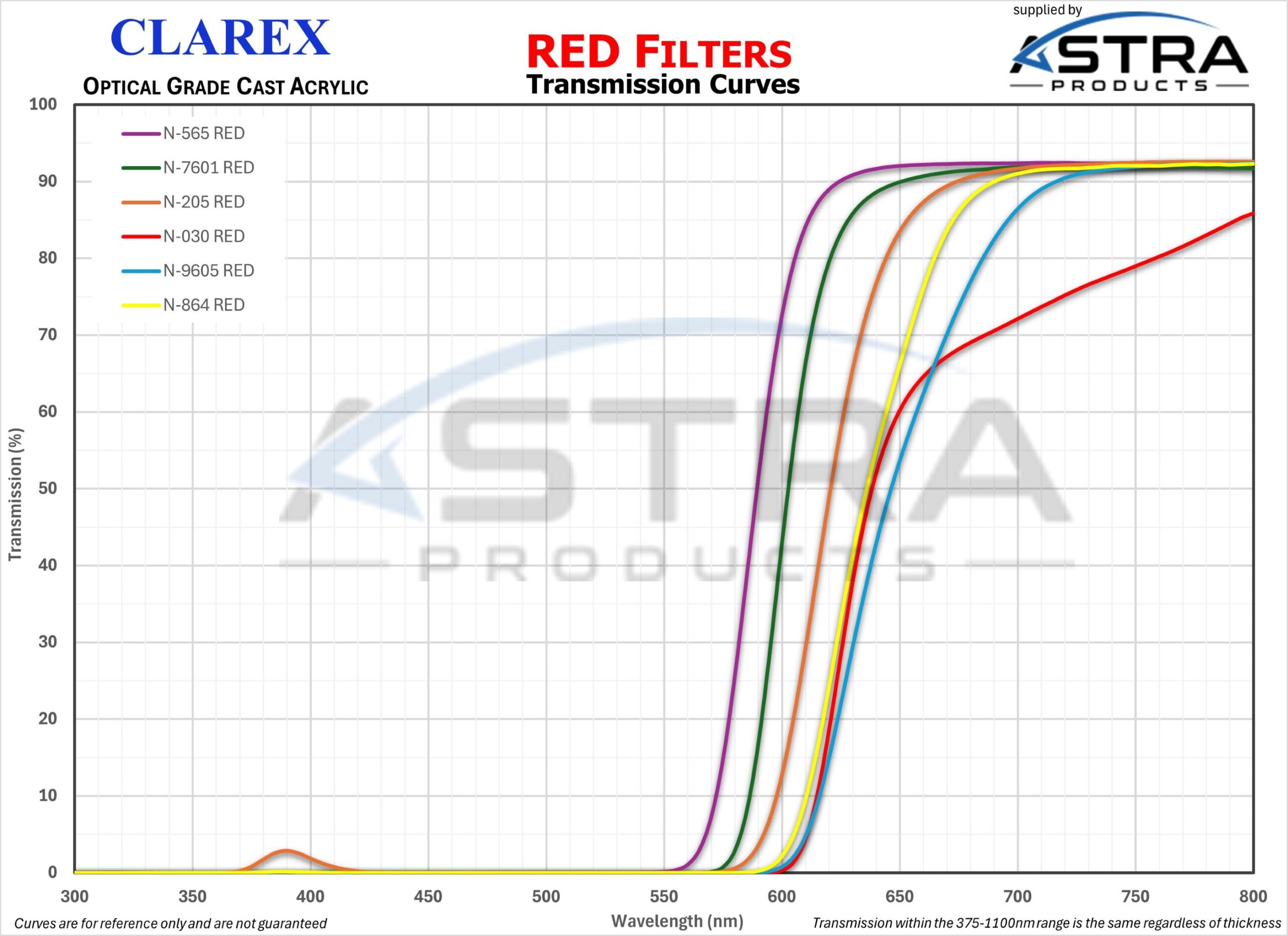

Transmission Curves for Standard Clear Acrylic Sheets and Many Different Colors/Shades

We have additional specialty curves, such as:

Customization

Custom sheets & parts to meet the needs of your applications.

Build your own sheets! Do you have a unique design requirement that cannot be met with off-the-shelf acrylic sheets? The CLAREX sheets can be fully customized and produced in low volumes up to mass production. Choose the thickness, formulation, additives, color dye/pigments, surface textures, surface coatings, and optical coatings for your custom material configuration, and we can typically have it ready for you in 4-8 weeks. We can even fabricate the finished parts for you.

Physical & Chemical Properties of Cell-Cast Thin Acrylic Sheets

| PROPERTY | METHOD | UNIT | UNCOATED | WITH HARD-COAT |

|---|---|---|---|---|

| Specific Gravity | ASTM D-792 | 1.19 | 1.19 | |

| OPTICAL | ||||

| Refractive Index | ASTM D-542 | 1.49 | 1.49 (1.54) | |

| MECHANICAL | ||||

| Elongation | ASTM D-638 | % | 5 | 5 |

| Tensile Rupture Strength | ASTM D-638 | kg/cm2 | 750 | 650 |

| Flexural Rupture Strength | ASTM D-790 | kg/cm2 | 1200 | 800 |

| THERMAL | ||||

| Heat Distortion Temperature | °C | 108 | 110 | |

| Maximum Recommended Continuous Temperature | °C | 80 | 80 | |

| Available with higher temperature ratings upon request, 90-95 °C | ||||

| DURABILITY | ||||

| Heat Resistance | 80ºC x 100hr | No Change | No Change | |

| Cold Resistance | -40ºC x 100hr | No Change | No Change | |

| Humidity Resistance | 60ºC x 90% x 100hr | No Change | No Change | |

| Thermal Cycle | -40ºC <> 80ºC (10 cycles) | No Change | No Change | |

| ELECTRICAL | ||||

| Surface Resistivity | w | 10^16 | 10^16 | |

| CHEMICAL | ||||

| Methyl Alcohol (50%) | No Change | No Change | ||

| Ethyl Alcohol (50%) | No Change | No Change | ||

| Soap Aqua Solution | No Change | No Change | ||

| Toluene | Dissolved | No Change | ||

| Acetone | Dissolved | No Change | ||

| Benzene | Swollen | No Change | ||

| Ethylene Dichloride | Dissolved | No Change | ||

| OTHER | ||||

| Pencil Hardness | 2H | >6H | ||

| Adhesion | K-5400 | 100/100 | ||

| FLAMMABILITY | ||||

| Fire Resistivity | UL standard | >=0.8mm Thickness | 94HB | 94HB |

What is Cell-Cast Acrylic?

Cell-cast acrylic is a premium type of acrylic known for its crystal-clear clarity, strength, and durability. Unlike other forms of acrylic, it’s made in a way that resists chemicals, warping/cracking, and birefringence, making it ideal for high-quality displays, optical filters, and other projects where a long-lasting high-quality material matters.

Ready to Get Started with Thin Cell-Cast Acrylic Sheets?

Whether you need standard sizes, custom fabrication, or a specialized formulation, our team can help configure CLAREX acrylic to meet your exact requirements.