CLAREX SUPER-Hard-Coat Acrylic (RHG)

Even higher scratch resistance than the standard hard-coat.

The CLAREX SUPER-Hard-Coat has 9H pencil hardness which is a step up from the standard hard-coat which has 6-8H pencil hardness. The tradeoff is that the sheets do become more brittle, and more expensive. So they work well for high abrasion applications, but not so well if there will also be impacts.

Benefits

- Even more scratch resistant than the standard hard-coat

- Optical Grade Cell-Cast Acrylic

- Coating on one or both sides

- Available with 9H SUPER-Hard-Coat on one side and 6-8H Standard Hard-Coat on the second surface for improved impact resistance

- No retardation / no birefringence

- Available with non-glare textures

Applications

- Protective window for flat panel displays

- Scanner bed windows

- Barcode scanner exit windows

- Camera enclosure windows

- Machine vision

- Sensor windows

Thicknesses

- 0.2mm

- 1.5mm

- 0.3mm

- 2.0mm

- 0.4mm

- 2.5mm

- 0.5mm

- 3.0mm

- 0.6mm

- 3.5mm

- 0.7mm

- 4.0mm

- 0.8mm

- 4.5mm

- 1.0mm

- 5.0mm

- 1.2mm

- Custom

Sheet Size

- 400 x 550mm sheets standard

- Custom sizes available upon request, up to 1000x1000mm in some cases

Customization

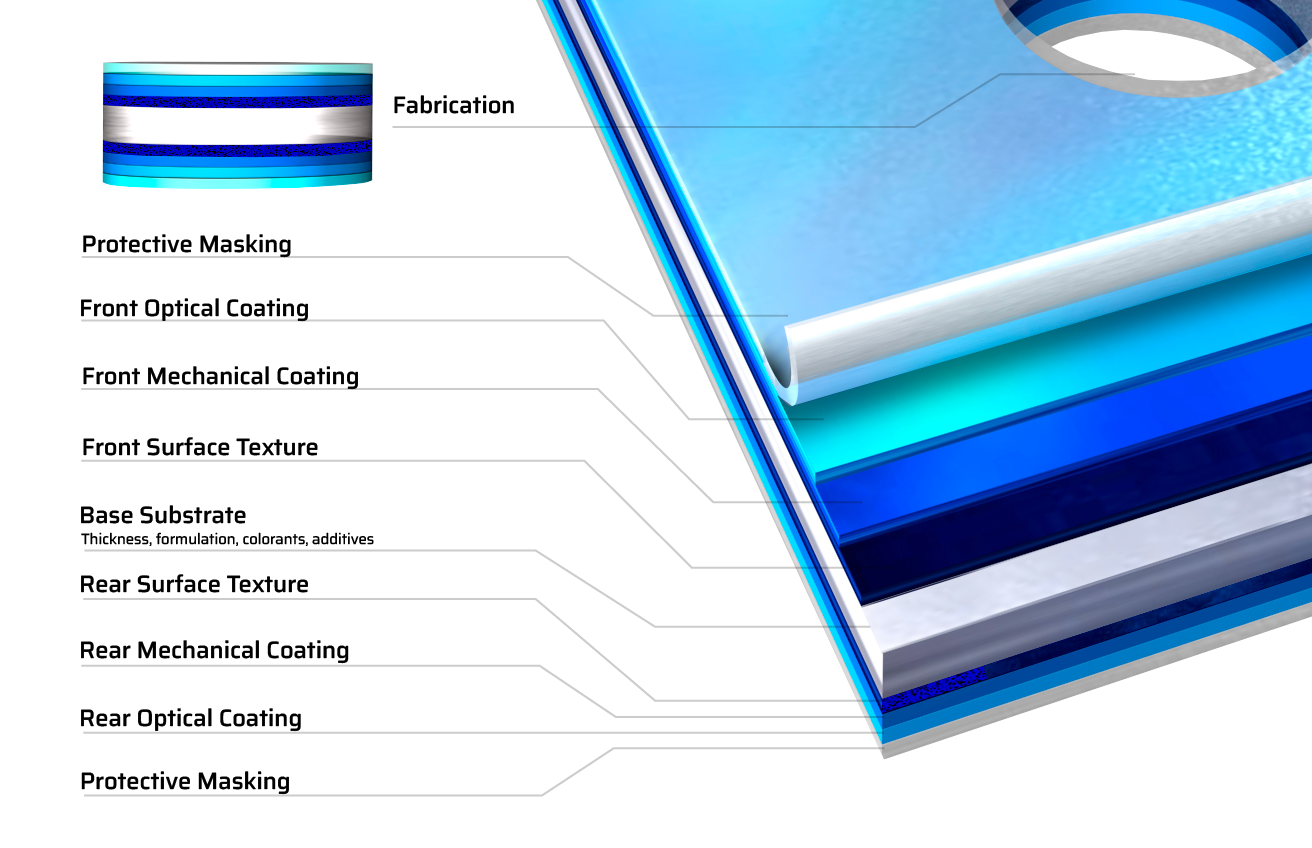

Custom sheets & parts to meet your application

Do you have a unique design requirement? We can help! Choose the thickness, formulation, additives, color dye/pigments, surface textures, surface coatings, and optical coatings for your custom material configuration, and if we don’t already have it in stock at our warehouse in New York, we can typically have it ready for you in 4-8 weeks. We can even fabricate the finished parts for you.

Properties of CLAREX Super-Hard-Coat PMMA Sheet

| Property | Method | Super Hard-Coat RHG20 |

|---|---|---|

| Pencil Hardness | 45 Degree at 1kg Load(JIS K5600) | 9H |

| Coating Adhesion | Cross Cut Measurement (100 Squares) | 100 / 100 |

| Abrasion Resistance | 0000 Steel Wool 10 Cycle at 1kg Load | NO SCRATCH |

| Total Light Transmittance | Measured by Haze Meter (JIS K7105) | 92% |

| Haze | 0.17% | |

| Heat Deflection Temperature | JIS K7121 | 110°C |

| Coefficient of Thermal Expansion | JIS K6911 | 7×10-5 cm/cm°C |

| Max Recommended Continuous Temperature | 80 °C |