CLAREX UV-Cut Acrylic

Blocks more UV than the standard clear sheets.

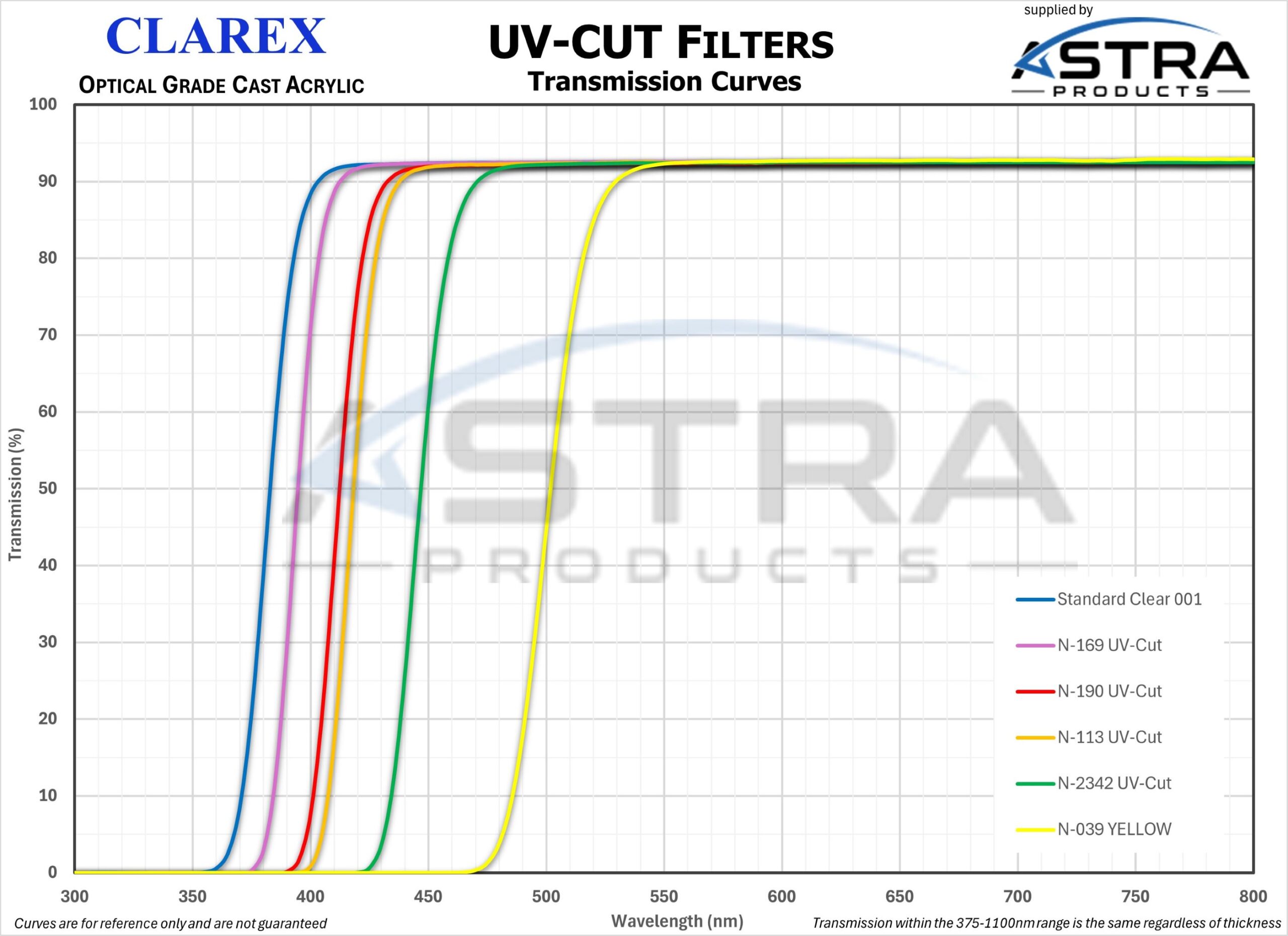

The standard CLAREX cast acrylic sheets include UV inhibitors which block UV below 375nm. The CLAREX UV-Cut filters are available for applications which require additional UV filtering. The factory has several options which block UV up to 480nm. Note that as the cut-in gets higher the sheets start to get a yellow tint. The N-039 is essentially a yellow filter.

Benefits

- Excellent optical characteristics

- No birefringence or double refraction

- Excellent weatherability

- Available smooth surface or non-glare surface

- Available with scratch & chemical resistant hard-coat

UV-Cut Filters are used in applications which are sensitive to UV light.

Applications

- Display protectors

- Optical filters

- Instrumentation

- Sensor windows

Thicknesses

- 0.2mm

- 1.5mm

- 0.3mm

- 2.0mm

- 0.4mm

- 2.5mm

- 0.5mm

- 3.0mm

- 0.6mm

- 3.5mm

- 0.7mm

- 4.0mm

- 0.8mm

- 4.5mm

- 1.0mm

- 5.0mm

- 1.2mm

- Custom

Size

- 400 x 550mm is standard small sheet

- 1000 x 1000mm is standard large sheet size

- Max size depends on several factors

- Please contact us to discuss standard and custom sheet size options.

Example Transmission Curves

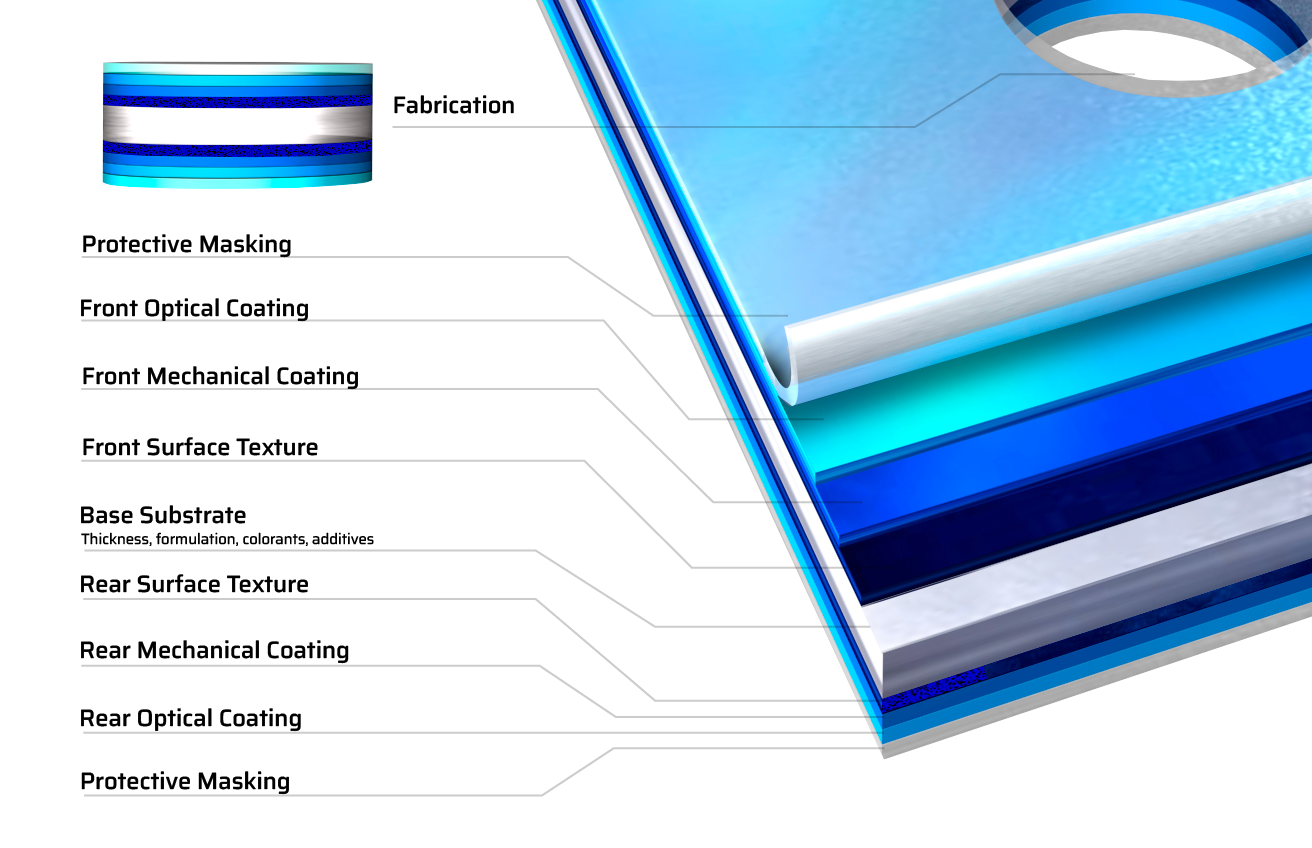

Customization

Custom sheets & parts to meet your application

Do you have a unique design requirement? We can help! Choose the thickness, formulation, additives, color dye/pigments, surface textures, surface coatings, and optical coatings for your custom material configuration, and if we don’t already have it in stock at our warehouse in New York, we can typically have it ready for you in 4-8 weeks. We can even fabricate the finished parts for you.

Physical & Chemical Properties of CLAREX UV-Cut Filters

| Property | Method | Unit | UNCOATED | with HARD-COAT |

|---|---|---|---|---|

| Specific Gravity | ASTM D-792 | 1.19 | 1.19 | |

| Optical | ||||

| Refractive Index | ASTM D-542 | 1.49 | 1.49 (1.54) | |

| Mechanical | ||||

| Elongation | ASTM D-638 | % | 5 | 5 |

| Tensile Rupture Strength | ASTM D-638 | kg/cm2 | 750 | 650 |

| Flexural Rupture Strength | ASTM D-790 | kg/cm2 | 1200 | 800 |

| Thermal | ||||

| Heat Distortion Temperature | ASTM D-648 | °C | 110 | 110 |

| Maxiumum Recommended continuous temperature | °C | 80 | 80 | |

| *Available with higher temperature ratings upon request, 90-95 °C | ||||

| Coefficient of Thermal Expansion | ASTM D-696 | cm/cm/ºC | 7 x 10-5 | 7 x 10-5 |

| Specific Heat | ASTM D-638 | cal/grºC | 0.3535 | 0.35 |

| Durability | ||||

| Heat Resistance | 80ºC x 100hr | No Change | No Change | |

| Cold Resistance | -40ºC x 100hr | No Change | No Change | |

| Humidity Resistance | 60ºC x 90% x 100hr | No Change | No Change | |

| Thermal Cycle | -40ºC <> 80ºC (10 cycles) | No Change | No Change | |

| Electrical | ||||

| Surface Resistivity | w | 10^16 | 10^16 | |

| Chemical | ||||

| Methyl Alcohol (50%) | No Change | No Change | ||

| Ethyl Alcohol (50%) | No Change | No Change | ||

| Soap Aqua Solution | No Change | No Change | ||

| Toluene | Dissolved | No Change | ||

| Acetone | Dissolved | No Change | ||

| Benzene | Swollen | No Change | ||

| Ethylene Dichloride | Dissolved | No Change | ||

| Other | ||||

| Pencil Hardness | 2H | 6~8H | ||

| Adhesion | K-5400 | 100/100 | ||

| Flammability | ||||

| Fire Resistivity | UL standard | >=0.8mm Thickness | 94HB | 94HB |