CLAREX® Anti Reflection Filters (AR Acrylic)

Additional coatings prevent surface scratching and smudging

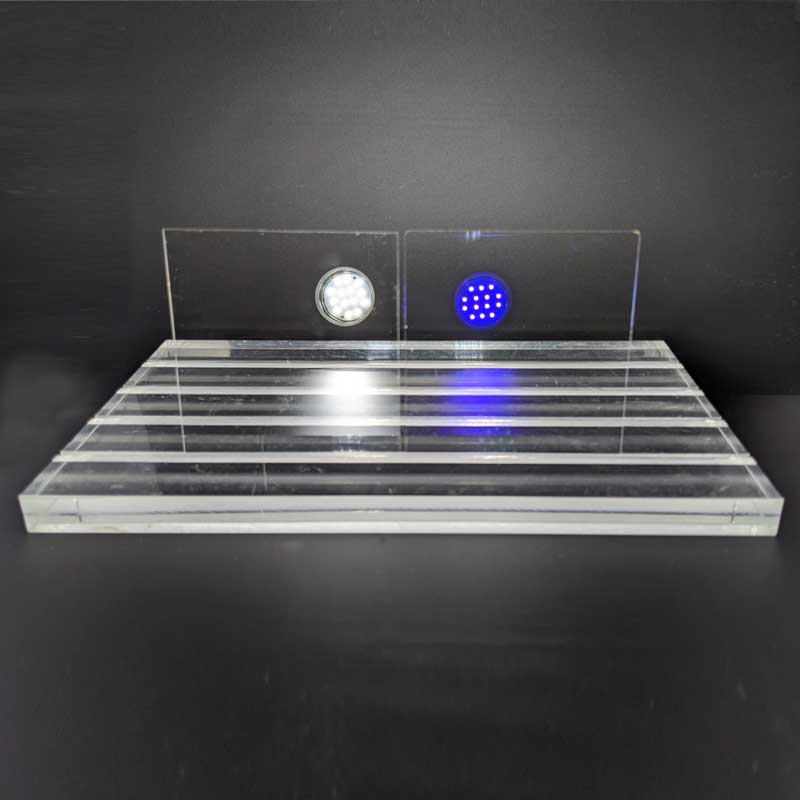

COATED vs. UNCOATED: An uncoated piece of acrylic on one side and an antireflection coated piece on the other side.

Reflection of a very bright light source. The sample on the right (with blue reflection) has AR coating. Reflection intensity is much lower.

CLAREX® AR COAT FILTER - is treated with a multi-layer AR coating which prevents light reflection. Additional coatings prevent surface scratching and smudging. May be combined with non-glare surfaces to further reduce reflection.

APPLICATIONS - Anti-reflection panel for LCD, CRT, LET, EL, PDP, VFD, FED, bar code scanners, etc.

THICKNESS - 0.2 to 5.0mm

SIZES - 290mm x 360mm standard | Custom sizes available upon request.

TYPES - Anti-reflection available one side or

two sides with or without anti-smudge coating.

Custom-tuned anti-reflection coatings are

available for NIR or UV applications –

contact us.

MACHINING / PRINTING - Available to customer specification.

- Excellent optical characteristics & reflection prevention

- Excellent transmission, greater than 98% visible range

- Excellent surface hardness & impact resistance

- Excellent smudge resistance. Anti-smudge coating makes the surface easier to clean (but cannot 'prevent' fingerprints).

COLORS - Available in clear and many colors. See standard colors.

Custom-Tuned AR Coatings Available!

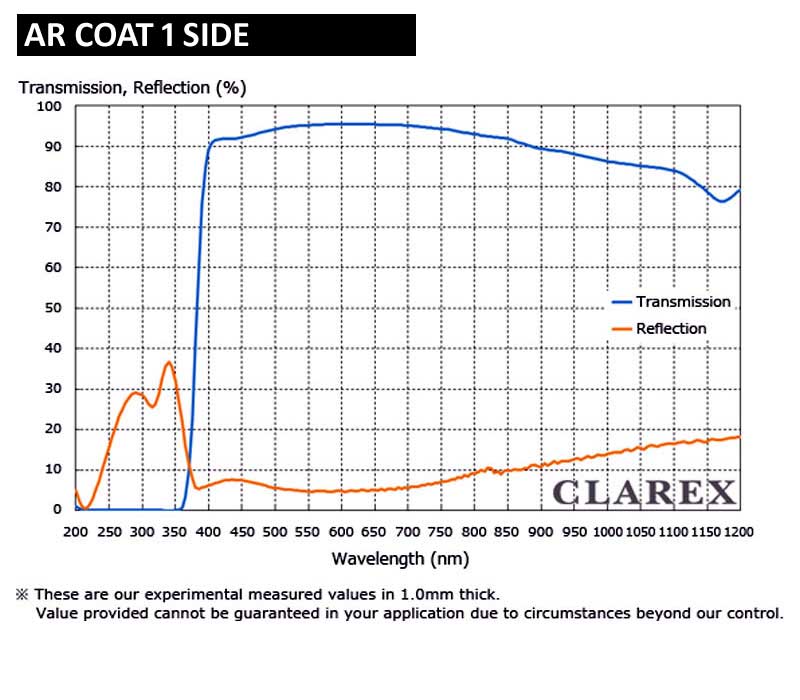

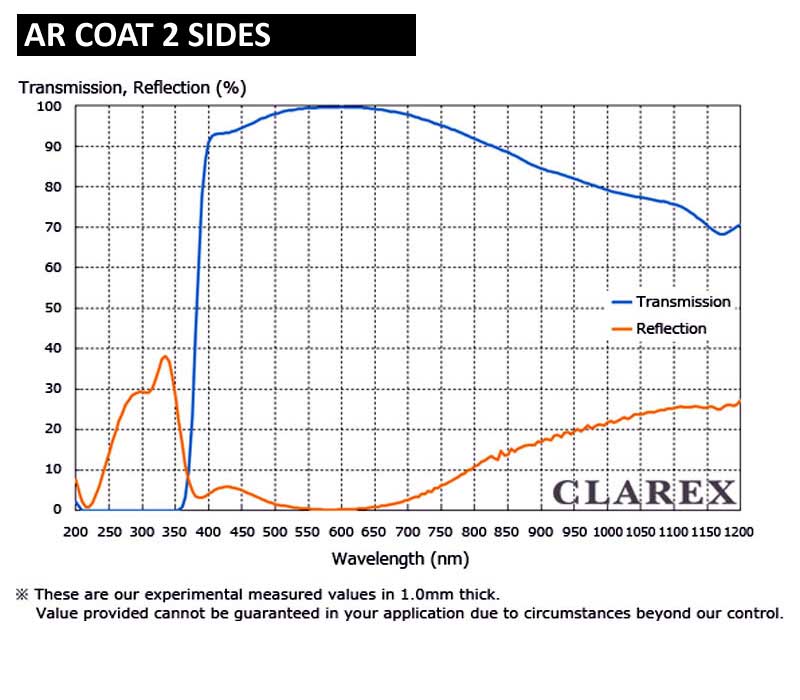

Transmission/Reflection Plots for Standard AR Coating One Side and Both Sides

(click images to enlarge)

| PHYSICAL PROPERTIES | |||

|---|---|---|---|

| PROPERTY | METHOD | UNIT | Value |

| SPECIFIC GRAVITY | ASTM D-792 | 1.19 | |

| Elongation | ASTM D-638 | % | 5 |

| Flexural Rupture Strength | ASTM D-790 | kg/cm2 | 800 |

| Heat Distortion Temperature | ASTM D-648 | ºC | 110 |

| Maximum recommended continuous temperature | ºC | 80 | |

| Available with higher temperature ratings on request, 90-95ºC | |||

| Coefficient of Thermal Expansion | ASTM D-696 | cm/cm/ºC | 7 x 10-5 |

| Heat Resistance | 80ºC x 100hr | No Change | |

| Cold Resistance | -40ºC x 100hr | No Change | |

| Humidity Resistance | 40ºC x 90% x 100hr | No Change | |

| Thermal Cycle | -40ºC <> 80ºC (10 cycles) |

No Change | |

| Sunshine Weather Meter | 100 hr | No Change | |

| Pencil Hardness | 6~8H | ||

| Shed Water (Touch Angle) | 114º | ||

| CHEMICAL | |||

| Isopropyl Alcohol (50%) | No Change | ||

| Soap Aqua Solution | No Change | ||

| Water | No Change | ||

| Sulfuric Acid | Dissolved | ||

| Sodium Carbonate | Dissolved | ||